Industrial facilities are structures housing complex functions like production, distribution, and energy management. At the heart of the energy infrastructure in these facilities lies correctly selected and appropriately configured electrical panels. Panels are critical for the orderly operation and safety of electrical systems.

The Relationship Between Industrial Facilities and Electrical Panels

Industrial facilities have varying operating conditions and load capacities. Therefore, the electrical panel to be used must be specifically determined for the facility. Incorrect panel selection can lead to energy losses, malfunctions, and even situations threatening life and property safety. Factors to consider when choosing a panel include panel size, material type (sheet steel, stainless steel, polyester, etc.), IP protection class, and cooling needs. All factors such as the size of the Industrial Facilities, working environment conditions, and required safety levels should be taken into account in panel selection.

Technical Criteria to Consider in Panel Selection for Industrial Facilities

When determining the suitability of an electrical panel for industrial use, some technical details must be carefully considered. These include:

- IP Protection Class: Indicates resistance to dust and water in Industrial Facilities.

- Ventilation and Cooling: Prevents the heating of components inside the panel of Industrial Facilities.

- Size and Modularity: Should have an expandable structure and be adaptable to future needs of Industrial Facilities.

- Cable Entry-Exit Structure: Should allow for easy wiring in Industrial Facilities.

In addition to these criteria, panel systems chosen for Industrial Facilities should also be long-lasting and easy to maintain.

The Role of Industrial Cable Support Systems in Industrial Facilities

When evaluated together with panels, industrial cable management systems play a complementary role in the overall energy infrastructure of Industrial Facilities. The correct and safe routing of cables is indispensable for both operational continuity and safety within Industrial Facilities.

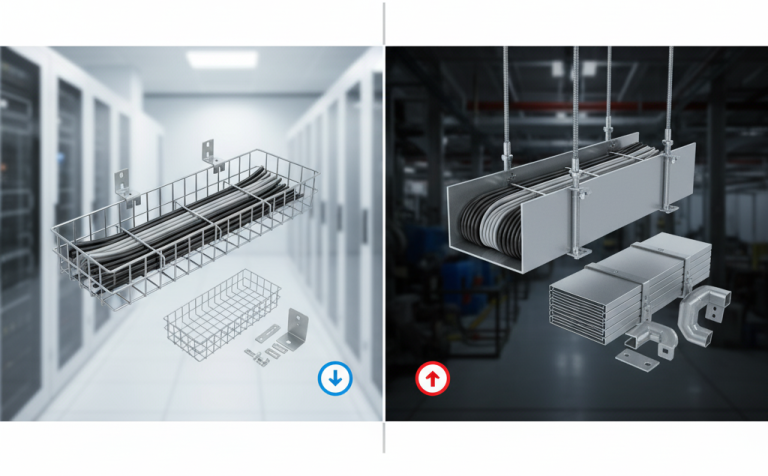

Industrial cable support systems typically come in the following types for Industrial Facilities:

- Cable Ducts: Made of plastic or metal. They protect cables from physical impacts and ensure orderly routing within Industrial Facilities.

- Cable Ladders: Used for carrying heavy cables over long distances.

- Cable Trays: Preferred especially in ceiling-mounted systems within ındustrial Facilities. They can carry large groups of cables.

- Carrier Rail Systems: Used for cables working with moving machinery.

The correct selection and installation of these systems ensure the healthy maintenance of connections within the panel. They also contribute to the safe and traceable distribution of electricity throughout Industrial Facilities.

Correct Placement and Planning for Electrical Panels in Industrial Facilities

Not only the technical features of the panel but also the location where it will be positioned is very important. When planning the panel placement, the following points should be considered:

- Locations away from fire risks should be preferred in Industrial Facilities.

- Moist or wet areas should be avoided within Industrial Facilities.

- Locked systems should be used to prevent unauthorized access in Industrial Facilities.

- Sufficient space should be left around it for ease of maintenance and intervention in Industrial Facilities.

All these criteria extend the lifespan of the panel while minimizing the risk of failure in Industrial Facilities.

Suitable Panel Types for Industrial Facilities

Considering different production areas and working conditions, the most common panel types for Industrial Facilities are as follows:

- Distribution Panels: Ensure the proper distribution of electrical energy from the main source to various points within Industrial Facilities. Main and sub-distribution panels are used together in large industrial plants.

- Motor Control Centers (MCC): Industrial Facilities housing a large number of motors can control each motor separately thanks to these types of panels.

- Automation Panels: These are panels where PLC and SCADA systems are located, crucial for the operation of Industrial Facilities. Process control, sensor data, and system automation are carried out through these panels in Industrial Facilities.

- Compensation Panels: These panels, which balance reactive power consumption and reduce energy bills, are of critical importance, especially in Industrial Facilities with heavy industry.

Compatibility with Digital Tracking and Automation Systems in Industrial Facilities

Today, Industrial Facilities are being integrated into smart systems with the impact of digitalization and automation. This necessitates the preference for products compatible with new generation control and monitoring systems in panel selection for Industrial Facilities. Panels that can work with systems such as SCADA and PLC increase the energy efficiency of the operation while facilitating fault management within Industrial Facilities.

Energy Efficiency and Sustainability for Industrial Facilities

In today’s world, where energy costs are increasing, energy efficiency is of critical importance for Industrial Facilities. Optimized infrastructure with the right panel selection and cable management systems reduces energy losses and contributes to the uninterrupted operation of production processes within Industrial Facilities. Additionally, reducing the carbon footprint can be achieved in terms of sustainability for Industrial Facilities.

Quality and Certifications of Panel Manufacturers for Industrial Facilities

When choosing a panel for Industrial Facilities, not only technical specifications but also the reliability of the manufacturer should be considered. Products with quality certificates such as ISO, TSE, and CE demonstrate compliance with international standards. In this way, Industrial Facilities can operate in accordance with both local regulations and international norms.

Conclusion: Choosing the Right Panel in Industrial Facilities

The appropriate panel selection for Industrial Facilities, when evaluated together with cable management systems, is indispensable for a facility to operate efficiently, safely, and sustainably. Mastering technical details, ensuring compatibility with current systems, and working with expert manufacturers are the most important steps in this process. At this point, working with experienced companies with a strong product portfolio like Delta Tema provides a great advantage for Industrial Facility. Thanks to correctly chosen panels and cabling systems, Industrial Facilities operate with fewer failures, more production, and maximum safety. With the quality and sustainable panel solutions offered by Delta Tema, Industrial Facility achieve significant gains in terms of long-term energy efficiency and operational continuity.