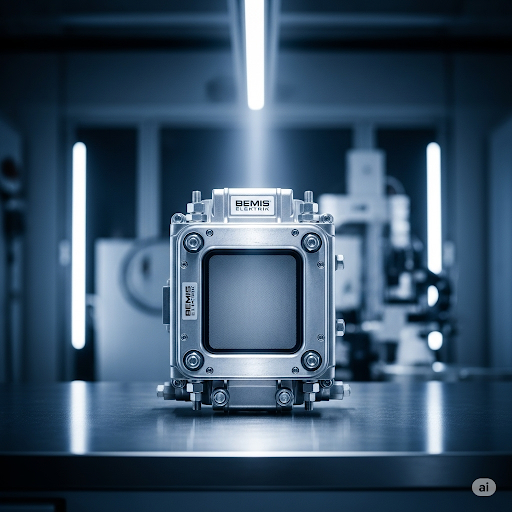

Industrial facilities, oil refineries, chemical factories, and mining sites are hazardous environments filled with potential risks where even the smallest spark can lead to major disasters. Ensuring the safety of workers and equipment in these areas is the top priority. That’s where Bemis Electric Ex-proof Products, specially designed for these challenging conditions, come into play. With the safe solutions in hazardous environments they provide, they minimize explosion and fire risks, elevating the safety of businesses and employees to the highest level. Bemis’s expertise in this field has been proven with products that meet the strictest international safety standards.

What is Ex-proof and Why is it Crucially Important?

Ex-proof is an abbreviation of “explosion-proof” and refers to equipment designed to be resistant to explosions. In hazardous areas containing flammable gases, vapors, dust, or fibers, electrical equipment must be specially designed to prevent any internal sparks from leaking outside and triggering an explosion. These devices are used in areas where explosive substances are within ignition limits to prevent accidents. Bemis Electric products are manufactured precisely to meet this vital safety requirement.

Ex-proof products are not only a standard but also a mandatory requirement defined by international regulations such as ATEX and IECEx. The goal of these products is to contain any internal explosion or spark, preventing it from spreading to the external explosive atmosphere. This is one of the cornerstones of industrial safety regulations, and neglecting it can lead to irreversible consequences.

Bemis Electric’s Safety Commitment and Quality Standards

For many years, Bemis has been recognized as a trusted brand in the electrical industry for its reliability and quality. Especially with its Ex-proof products, the company has established a strong position in the sector. High-quality materials used in manufacturing and rigorous quality control processes ensure that every Bemis Electric product can withstand the most challenging conditions. The explosion-proof solutions of the brand are designed considering the latest technological advancements and safety standards.

Bemis Electric not only sells products but also aims to secure its customers’ projects from start to finish by offering safe solutions in hazardous environments. The company’s expertise in this area is further validated through certifications and international audits. Relying on your equipment when working in hazardous areas is critical for both operational continuity and the safety of your employees.

Application Areas of Bemis Ex-proof Products

Bemis Electric Ex-proof Products are widely used across different industries. These products are particularly ideal for areas where explosive materials are produced or stored. Main application areas include:

- Oil and Gas Industry: Refineries, filling stations, and pipelines.

- Chemical and Petrochemical Plants: Production areas where flammable and toxic chemicals are processed.

- Pharmaceutical and Food Industry: Production and storage areas where explosive dust can form.

- Mining: Underground mines containing methane gas and coal dust.

- Textile and Wood Industry: Processing areas with flammable fibers and dust.

Every electrical component used in these areas must be equipped with special safety measures. The button boxes and other control equipment offered by Bemis Electric fully meet these requirements.

Technical Features of Explosion-proof Products

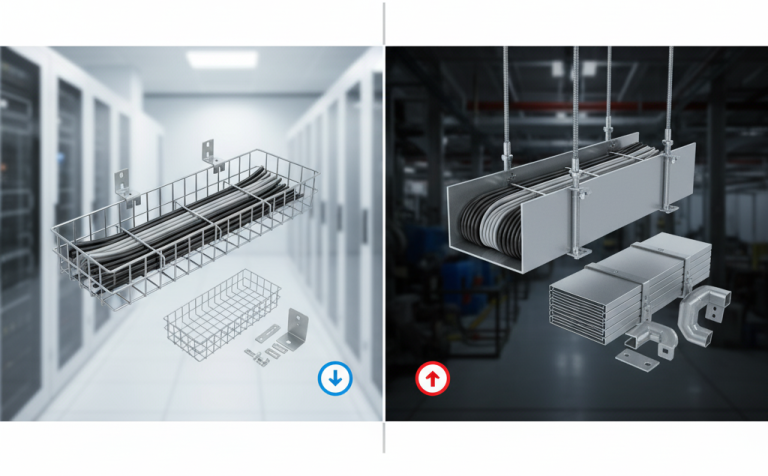

What distinguishes a Bemis Electric Ex-proof product from others is not only its design but also its technical features that make it suitable for hazardous environments. The essential features these products must have include:

- Protection Class: Products generally have a protection rating of IP66 or higher, meaning they provide full protection against dust and strong water jets.

- Material Structure: Their enclosures are made of robust materials (often reinforced polyester) that can absorb explosion energy and prevent flames from escaping.

- Certifications: They must be certified under international explosion protection standards such as ATEX and IECEx. This proves the products have passed independent tests and are safe.

- Temperature Class: They are classified according to the explosion temperature of the environment they operate in, ensuring that surface temperatures do not exceed a certain limit.

These features form the foundation of how each product delivers safe solutions in hazardous environments.

Why Delta Tema for Bemis Products?

Delta Tema is a trusted partner of Bemis Electric and offers the brand’s Ex-proof products across a wide range. By choosing Delta Tema, you not only receive high-quality products but also benefit from expert technical support and fast delivery. Selecting and installing the right product for your projects is critically important, and Delta Tema’s experienced team guides you through this process. Quality materials and proper implementation maximize your safety. Visit Delta Tema’s website to learn more about other services offered.

Conclusion

Bemis Electric Ex-proof Products are one of the cornerstones of industrial safety. For every business operating in hazardous and potentially explosive environments, these products are a necessity. The quality and expertise of Bemis Electric in this field ensure operational continuity and worker safety even under the most challenging conditions. Remember, providing safe solutions in hazardous environments is not only a legal obligation but also an ethical responsibility. No compromises should ever be made on this matter. Visit the official website of Bemis Electric for more detailed information about the products.