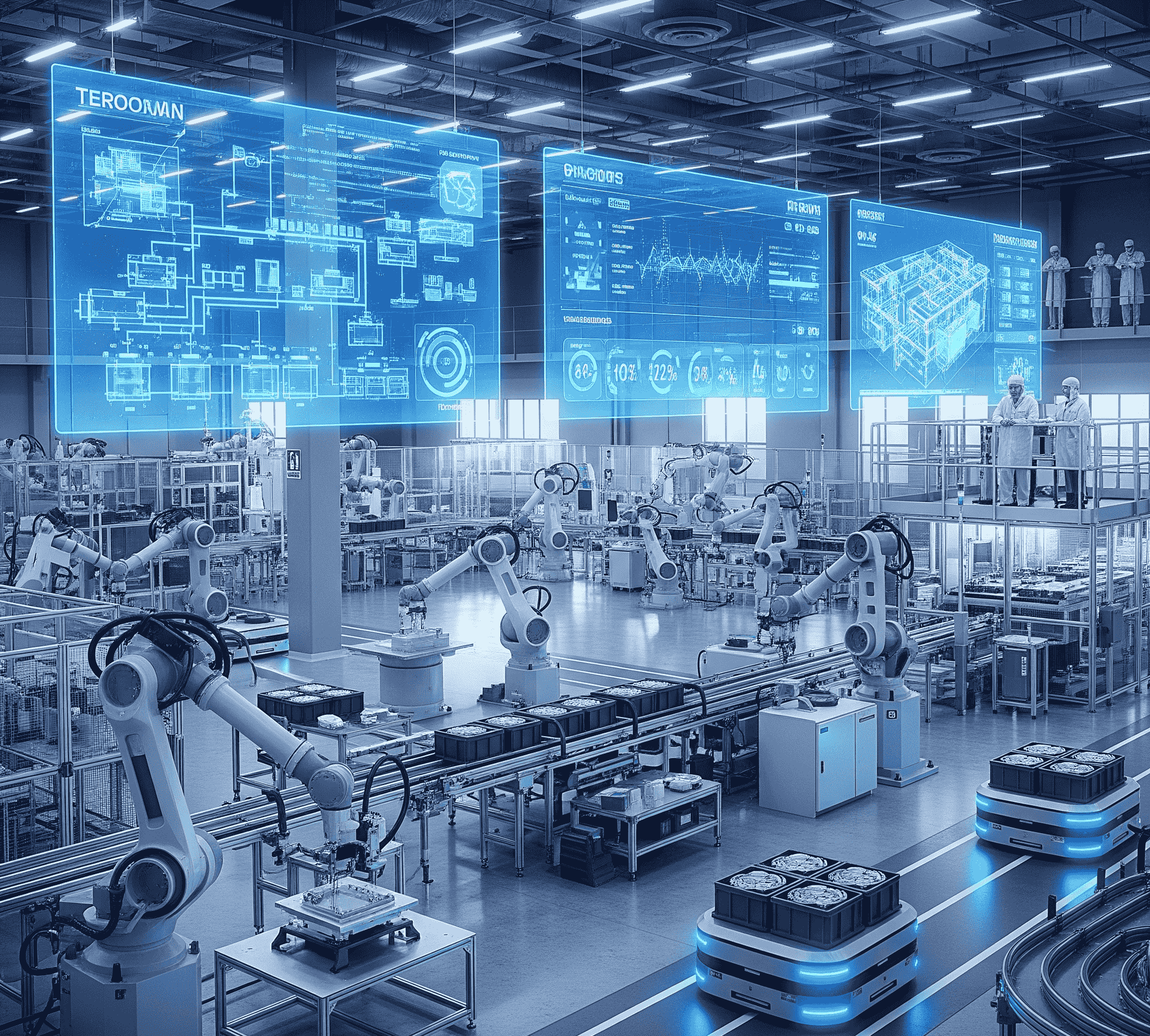

The business world is undergoing a radical transformation with the Industry 4.0 revolution. Production processes are becoming smarter, more efficient, and more autonomous every day. At the heart of this transformation is the concept of industrial automation and smart factories. Machines and systems communicate seamlessly with each other and with people, revolutionizing production. However, at the core of this advanced technology lie the right and reliable electrical solutions. How “smart” a factory is is directly linked to the quality of its electrical infrastructure.

In this blog post, we will examine the main elements that make a factory smart and the fundamental electrical solutions Deltatema offers in this process.

Why Are Industrial Automation and Smart Factories Important?

Industrial automation and smart factories offer countless advantages to businesses:

- Increased Efficiency: Automation systems ensure production processes run faster, with fewer errors, and without interruption. This maximizes production capacity while reducing costs.

- High Safety: By using robots and machines instead of humans for dangerous tasks, workplace accidents are minimized. The right switchgear and protection systems eliminate electrical risks.

- Flexibility: Smart systems can be quickly reprogrammed and adapted for different product types. This makes it possible to respond instantly to changing market demands.

To realize these benefits, choosing the right electrical and automation materials is a critical step.

The Electrical Solutions at the Heart of Smart Factories

For a factory to become “smart,” every component used must work in harmony. Underneath this complex structure lies a wide range of electrical materials, from correctly chosen PLCs to sensors, cables, and motors.

Control Systems and PLCs

The brain of smart factories is the programmable logic controller (PLC). These devices manage production lines, control machine operations, and monitor all processes. For industrial automation and smart factories, high-performance PLCs from reliable brands like Siemens ensure the system runs smoothly.

Sensors and Data Collection Devices

For a factory to be truly smart, it must have real-time data. Sensors collect information such as temperature, pressure, position, and speed, and transfer this data to the PLCs. This allows potential faults to be detected in advance and energy consumption to be optimized.

Motor Control Systems and Human-Machine Interfaces (HMI)

The efficient management of motors, the beating heart of production lines, is fundamental to the smart factory concept. Variable Frequency Drives (VFDs) precisely control motor speed and torque, both optimizing energy consumption and reducing mechanical wear. This extends the life of motors and lowers maintenance costs.

For factory workers, Human-Machine Interfaces (HMIs) make it easy to manage complex automation systems. HMI panels provide operators with a live visual of the production process, speed up fault diagnosis, and allow for intuitive input of control commands. These devices are indispensable for real-time monitoring of production data.

The Role of Safety and Data Analytics in Smart Factories

The topics of Industry 4.0 and industrial automation and smart factories are not just about efficiency; they are also about increasing safety and predictability. Safety is a primary priority, especially in environments with high concentrations of electrical and mechanical systems. Emergency stop buttons, safety relays, and proper grounding materials are critically important for preventing potential accidents. These materials guarantee the protection of both employees and equipment.

Furthermore, one of the biggest advantages offered by smart factories is data analytics. Large amounts of data collected from sensors and machines can be analyzed through advanced software to identify production bottlenecks, energy waste, and potential points of failure. Thanks to these predictive analyses, maintenance can be planned before a breakdown occurs, and the production line can continue to run without interruption. This smart use of data enables businesses to make more informed and strategic decisions.

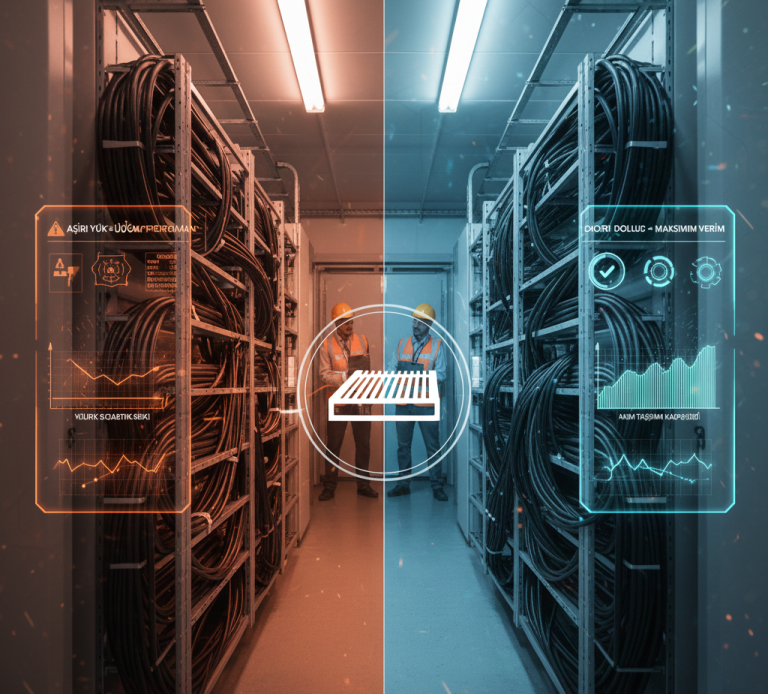

Cables and Connection Systems

A factory’s nervous system is its cables. Automation systems carry data and power to hundreds of different points. Industrial cables from quality brands like Prysmian and 2M Kablo protect data integrity and increase system reliability. Additionally, cable management systems offered by OBO Bettermann both facilitate installation and create a long-lasting and safe infrastructure. For all solutions in this area, you can review the Deltatema products page.

Choosing the Right Solution Partner for Your Projects

Smart factory projects are not just about material supply. Success comes from providing the right materials at the right time and working with a partner who can offer technical support at every stage of the project. At Deltatema, with our years of industry experience and wide range of products, we are here to meet all your project’s electrical and automation needs. To get more information about our Our Services, you can visit our page.

We also recommend you review the TÜSİAD’s related reports for more information on the future of Industry 4.0 and digital transformation in Turkey.

Conclusion

Industrial automation and smart factories are setting the production standards of the future. To best utilize the opportunities this transformation brings, it is vital to choose the right electrical solutions from the very beginning and to proceed with a reliable partner. At Deltatema, we are ready to help you take your projects to the next level by combining the latest technology with the highest quality products.