Introduction: Data, Security, and the Noise Problem

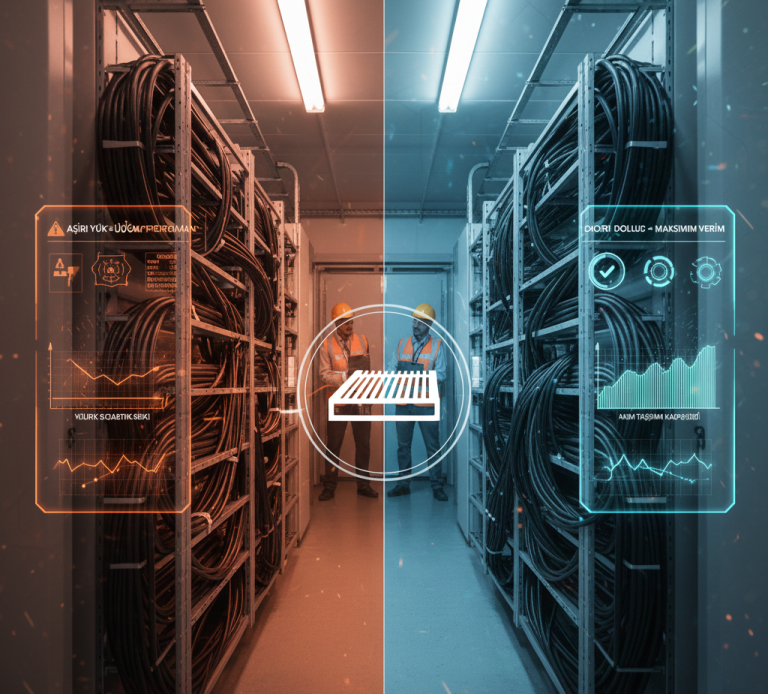

In the digital age, the heart of critical infrastructures relies on the uninterrupted flow of sensitive data and control signals. In environments such as data centers, smart factories (Industry 4.0), and hospitals, low-current (communication) cables must coexist with high-current (power) cables. However, electromagnetic noise generated by power cables, inverters, switched-mode power supplies, or lightning discharges can disrupt sensitive data signals, leading to system failures, data loss, and even equipment malfunction. This situation directly threatens project reliability and continuity.

This is precisely where Electromagnetic Compatibility (EMC) comes into play. EMC is the ability of a system to function acceptably within its electromagnetic environment while not generating an unacceptable level of electromagnetic disturbance in that environment.

In this article, we will explore the basic principles of EMC protection in cable tray systems, the passive methods used to provide this protection, and the vital impact of selecting the correct cable containment system on system integrity.

1. How Does EMC Noise Propagate and What Role Do Cable Trays Play?

Electromagnetic noise (disturbance) propagates in cable systems in two fundamental ways:

- Radiated Emission: This is the electromagnetic energy that cables or equipment emit into space. (E.g., Long cables acting as antennas).

- Conducted Emission: This is the direct propagation as current or voltage fluctuations through cables and metal structures.

The Role of Cable Tray Systems: A cable tray system, if not correctly designed and installed, can act as both a noise source and a path for noise propagation. Conversely, a correctly selected metal cable tray system can protect critical data cables by acting as a Faraday Cage that absorbs and redirects noise.

2. EMC Protection in Cable Trays: The Faraday Cage Principle

The fundamental physical way to ensure data integrity is to isolate sensitive cables from external electromagnetic fields. The most effective way to achieve this is by utilizing metal cable trays as a Faraday Cage.

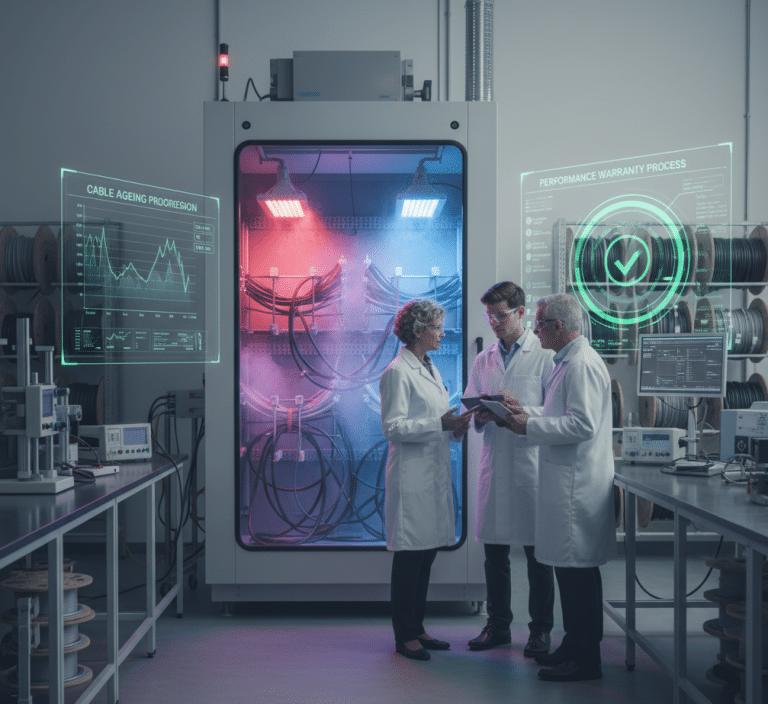

A Faraday Cage is a conductive enclosure that blocks external electromagnetic fields (whether static or rapidly varying). For the cable tray system to fulfill this function, two critical conditions must be met:

A. High Conductivity (Material Selection)

The effectiveness of EMC protection depends on the conductivity of the cable tray material. While galvanized steel trays are commonly used, materials with high conductivity, such as aluminum or zinc-coated steel, are preferred for sensitive environments.

B. Perfect Continuity (Joints and Covers)

The weakest points of a Faraday Cage are its joints and openings. For the highest level of EMC protection, it is necessary to ensure:

- Continuous Earthing and Equipotential Bonding: All sections of the cable tray system (trays, bends, T-pieces, covers) must be connected to each other continuously and with low impedance, keeping the entire structure at a single potential. This ensures that noise currents are safely routed to the ground. EMC-compliant connecting elements (often with springs or conductive gaskets) guarantee this continuity.

- Complete Covering: The tray covers must be metal and conductive to prevent radiated noise from leaking inside. Continuous contact between the tray and the cover (again, via special gaskets or tight bolting) is critically important.

Internal Link: For a deeper understanding of equipotential bonding, which is an integral part of EMC protection and brings the entire system to a single potential, you can check our previous article:Equipotential Bonding in Lightning Protection Systems: Full Compliance with IEC Standards(This internal link directs to the previously suggested blog topic, translated to English for context)

3. Cable Separation and the Distance Rule (Passive Filtering)

The second and simpler form of EMC protection is to physically separate the noise source from the sensitive receiver.

- Power and Data Separation: Low-current (data) cables and high-current (power) cables must never be carried in the same tray. Separating the trays significantly reduces noise coupling.

- Metal Dividers: In mandatory situations, metal dividers (separators) used within the cable tray can create a barrier between the noise source and the data cable, providing a partial Faraday effect. However, this is not as effective as using entirely separate trays.

- Minimum Distance Rule: A specific minimum distance (generally $30-50$ cm) must be maintained vertically and horizontally between high-current trays and low-current trays.

4. Equipment Selection and Installation Quality

The success of EMC protection in cable tray systems depends on the quality of the installation. Even the best EMC tray loses its function if it is not connected properly (loose bolts, poor earthing).

- Connecting Elements: Instead of standard bolted connections, spring nuts and lock washers that maximize conductivity and ensure continuous contact should be used.

- Surface Treatment: The earthing contact surfaces of the cable tray and accessories must be completely free of paint or insulating materials.

Conclusion: EMC is Not Insurance, It’s a Design Requirement

In installations requiring critical data integrity, EMC protection is not an “additional measure” but a fundamental design requirement. Providing EMC protection in cable tray systems according to the Faraday Cage principle, using high-conductivity materials and ensuring total electrical continuity, directly increases system reliability and lifespan. Failed EMC implementations keep the risk of system failure and data loss constantly alive.

As Delta Tema Elektrik, we support your projects with EMC-compliant cable tray systems (solutions from leading brands like OBO Bettermann) that comply with IEC and EN standards to guarantee your data integrity and facility safety. Contact us immediately for solutions that deliver both safety and efficiency. Delta Tema Elektrik Contact Page