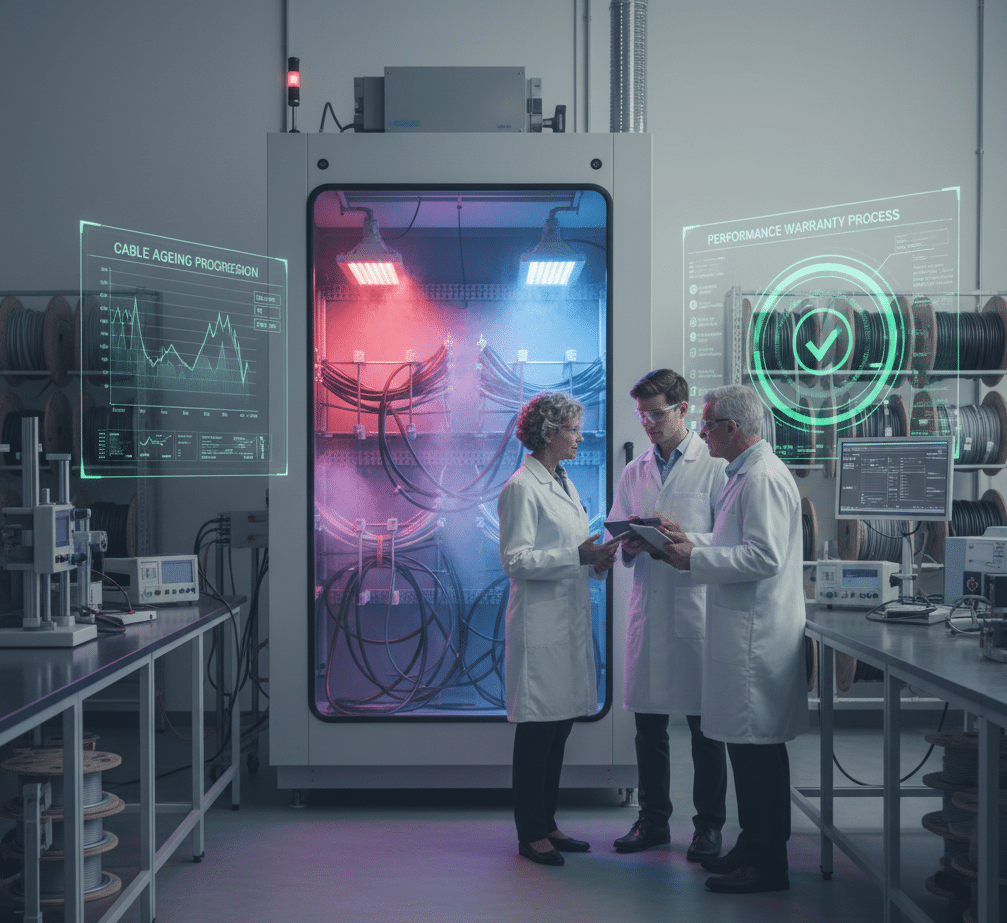

Cable Aging Tests and Performance Guarantee Process are the most vital technical processes determining the lifespan and safety of electrical infrastructure. A cable’s service life, whether underground, in a switchgear center, or in an automotive line, depends not only on the initial installation quality but also on its ability to resist thermal, electrical, and environmental stresses. Therefore, Cable Aging Tests and Performance Guarantee Process are crucial for protecting a project’s long-term investment value and preventing unexpected failures. Globally recognized brands like 2M Kablo and Prysmian guarantee this quality by subjecting their cables to the toughest tests under international standards (IEC).

In this comprehensive guide, we will examine the fundamental mechanisms of Cable Aging Tests and Performance Guarantee Process, the details of laboratory tests, and how this quality assurance adds value to your projects.

Fundamental Mechanisms Causing Cable Aging

Cables are constantly exposed to three main types of stress. These stresses slowly degrade the chemical and physical composition of the insulating material:

- Thermal Stress (Heat Effect): Heat generated by the current carried by the cable breaks down the chemical bonds of the insulating material (especially XLPE or PVC). Increasing operating time at high temperatures shortens the cable’s lifespan exponentially.

- Electrical Stress: Under high voltage (HV/MV), voids or foreign materials in the insulating material trigger events like Partial Discharge (PD). These events pierce the insulation, leading to permanent failure.

- Environmental Stress: Exposure to moisture, UV rays, chemicals, or mechanical vibration physically wears down the outer sheath and insulation. Water, in particular, can cause serious degradation in XLPE insulation called “water treeing.”

Critical Test Methods and Standards

Accurately predicting a cable’s lifespan and guaranteeing its performance is possible through accelerated laboratory tests. These tests simulate years of wear in a short period.

Thermal Aging Tests (IEC 60216)

Thermal aging is the most significant determinant of cable lifespan. The IEC 60216 standard determines the life of a cable’s insulation material by testing it under accelerated high-temperature conditions.

- Tmax (Maximum Operating Temperature): The highest temperature at which the cable can operate continuously (e.g., 90°C for XLPE).

- Thermal Life Index (TAI): Indicates the period during which the cable maintains its minimum expected characteristics throughout its service life. Brands like Prysmian offer life expectancy exceeding 30 years, proven by these tests.

Water Treeing and Dielectric Tests

These tests, applied especially to medium voltage and high voltage cable (XLPE), measure the cable’s resistance to moisture. The dielectric strength of the cable, submerged in water under high AC voltage for a long period, is tested. This determines how long the cable will operate safely in damp underground conditions in critical infrastructure projects.

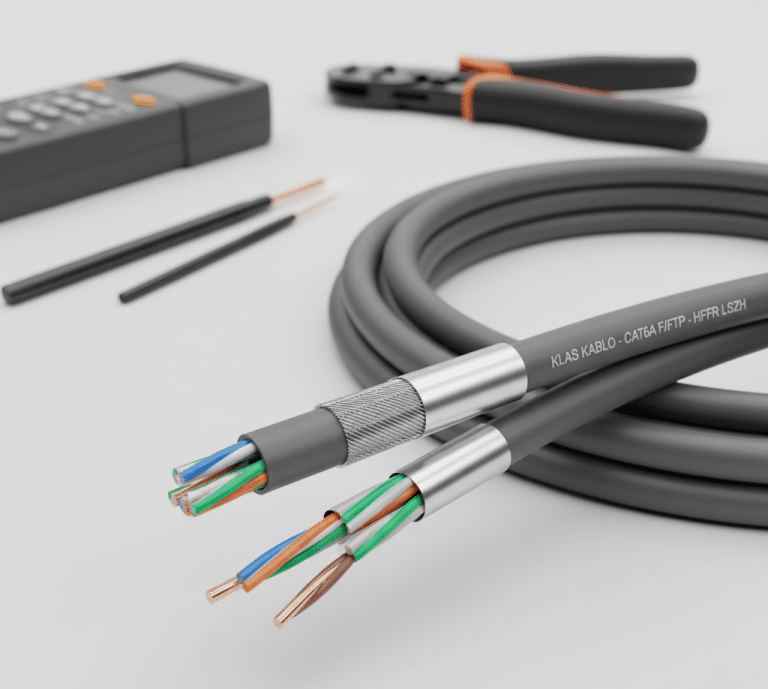

Prysmian and 2M Kablo: Two Brands of Quality Assurance

The products from 2M Kablo and Prysmian that we offer at Deltatema have passed these rigorous testing procedures. Their understanding of quality is the assurance of your long-term investment.

- Prysmian Innovation: Prysmian uses its R&D resources to produce cables that minimize dielectric losses and water treeing, utilizing special XLPE and EPR insulation compounds, as detailed in their technical documentation.

- 2M Kablo Reliability: 2M Kablo performs thermal aging tests on its products according to national and international standards, especially for fire safety (fire-resistant cable) and low-voltage cables. This guarantees safety in halogen-free cable solutions.

The Guarantee of Long-Term Investment with Deltatema

The data provided by the Cable Aging Tests and Performance Guarantee Process is fundamental for making the right choice for electrical projects. At Deltatema, we not only offer certified products but also convey the impact of these certifications on your project’s cable current carrying capacity and life expectancy.

- Technical Consulting: We provide expert consulting services to select the most thermally suitable cable by analyzing your project’s environmental conditions (temperature, humidity) and load factors.

- Product Supply: We manage the logistics and quality process of your project by supplying Prysmian and 2M Kablo products with approved cable cross-sections and features at the correct time and code.

Conclusion

The Cable Aging Tests and Performance Guarantee Process are vital for a project’s financial and operational health. By choosing the quality of Prysmian and 2M Kablo, you ensure that your cables will overcome not only today’s standards but also the challenges of the future. At Deltatema, we are proud to offer the assurance of this long-term investment.