In the world of modern architectural and industrial design, the “smart building” concept is no longer just an aesthetic preference; it is a strategic necessity that lowers operational costs and ensures environmental sustainability. Steinel, at the heart of this transformation, is a global representative of German engineering in the fields of lighting control, sensor technologies, and heat tools. However, for a building to be truly “smart,” high-quality Steinel sensors alone are not enough. The cabling infrastructure that powers these sensors and transmits data/control signals must be equally flawless and durable. Integrating Steinel technology with high-performance cables from brands like Prysmian or 2M Kablo ensures the highest level of comfort, maximum energy savings, and a long-term investment for any facility.

In this comprehensive guide, exceeding 700 words, we examine the technical requirements of Steinel sensor solutions, their critical role in energy efficiency, and how a correct cabling infrastructure adds immense value to these systems.

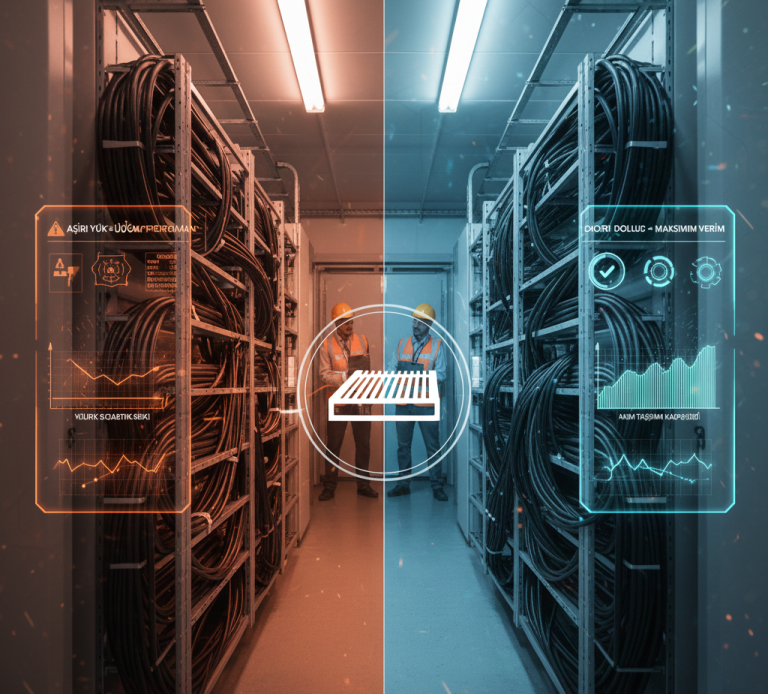

Steinel Sensor Technology and Cabling Architecture: The Neural Network

Steinel develops technologies that minimize energy consumption, particularly through presence and motion detectors. Activating a building’s lighting load only when occupants are present can provide up to a 90% improvement in annual energy costs. However, the seamless operation of this system relies on an architecture where the sensors act as the “brain” and the cables serve as the “neural network.”

- KNX and DALI Communication Protocols: Steinel’s professional series detectors communicate via KNX or DALI protocols—the standards of modern automation. In these systems, low-capacitance bus cables produced by 2M Kablo are critical to ensure data is transmitted without distortion. If electromagnetic interference (EMI) occurs on the data line, sensors may send false signals or lighting scenarios may activate with delays. Choosing the right cable ensures Steinel’s high-precision digital sensors operate at full performance.

- Power and Signal Integration: Power lines used in motion-sensor lighting groups undergo constant on-off cycles. To ensure stable voltage transmission during these cycles, high-quality conductors from Prysmian should be preferred. An infrastructure resistant to voltage fluctuations protects the technical lifespan of Steinel products and minimizes maintenance costs.

The Invisible Power of Cabling in Energy Efficiency

Steinel products are the first step for businesses aiming to reduce their carbon footprint through “smart lighting.” However, energy efficiency is not just about turning the lights off; it’s about reducing losses within the system itself.

- Voltage Drop and Conductor Quality: In sensor networks spread over large areas (e.g., logistics warehouses or tunnels), the risk of voltage drop increases with cable distance. High-purity copper conductors, which are the right choice for electrical projects, ensure energy reaches the sensor with minimal loss. Low-quality cables can damage the sensor’s sensitive electronic circuitry or cause inconsistencies in its detection range.

- Sustainability Integration: To create eco-friendly buildings, Steinel’s saving-oriented devices must be paired with Prysmian’s sustainable production philosophy. For green building certifications (LEED, BREEAM), every detail from cable choice to sensor type is reported. In this regard, Prysmian Group sustainability reports provide vital technical data support for projects.

Critical Infrastructure and Safety: Steinel Sensors During Fires

In critical infrastructure areas such as hospitals, parking garages, and high-rise business centers, lighting is a safety element, not just a comfort. During a fire or disaster, lighting the evacuation routes is of vital importance.

- Fire-Resistant Infrastructure: For Steinel sensors to manage emergency lighting during a fire, the lines powering these devices must be fire-resistant cable (FE180). A line protected by OBO Bettermann support systems and laid with fire-performance products from 2M Kablo ensures sensors continue data flow even in smoky and high-temperature environments.

- Halogen-Free Product Usage: Steinel sensors are typically located in suspended ceilings or enclosed areas. Using halogen-free cable (HFFR) in these areas protects life safety by preventing toxic gas emissions during a fire. Details on international safety standards can be followed via official IEC sources.

Deltatema: Engineering and Supply Power in Steinel Solutions

At Deltatema, we treat your project’s entire automation and energy ecosystem as a whole. We bring together Steinel’s smart sensors with the most suitable infrastructure components for your project.

- Technical Planning: We plan where each Steinel sensor should be placed according to your facility’s physical structure and the cable routes leading to these points through our expert consultancy services.

- System Compatibility: We ensure the Prysmian or 2M Kablo models used are fully compatible with the technical specifications of Steinel devices (current carrying capacity, data speed, etc.), eliminating failure risks caused by incorrect pairings.

- Fast Supply and Support: We deliver Steinel’s high-tech product range to your site with Deltatema’s rapid logistics power and technical support. You can view our product options here.

Conclusion

If Steinel smart sensors are a building’s “smart eyes,” the infrastructure built with Prysmian, 2M Kablo, and OBO Bettermann is the “strong neural system.” No matter how sharp the eyes are, if the neural system is weak, the building cannot function. Steinel technology, supported by a correctly planned cabling infrastructure, permanently lowers your operating costs, maximizes safety, and secures the long-term investment value of your facility.