The foundation of cyber resilience in industrial facilities is often not laid in software, but in the cabling infrastructure. A cabling system that is properly planned, built with the right products, and protected against environmental risks ensures data integrity, reduces system downtime, makes unauthorized interference more difficult, and enables industrial networks to remain operational in the face of cyberattacks. A weak or poorly designed infrastructure, on the other hand, can render even the most advanced cybersecurity software ineffective.

In this article, we examine in detail how cabling infrastructure determines industrial cyber resilience, why it is frequently overlooked in many projects, and what should be considered to build a secure and sustainable OT infrastructure in the long term.

Sources of Cyber Risk in Industrial Environments

Cyber resilience in industrial environments cannot be achieved solely through software and network components; the integrity of the physical infrastructure also plays a critical role. Nationally published cyber resilience frameworks clearly emphasize that industrial systems must be addressed through a multilayered security approach.

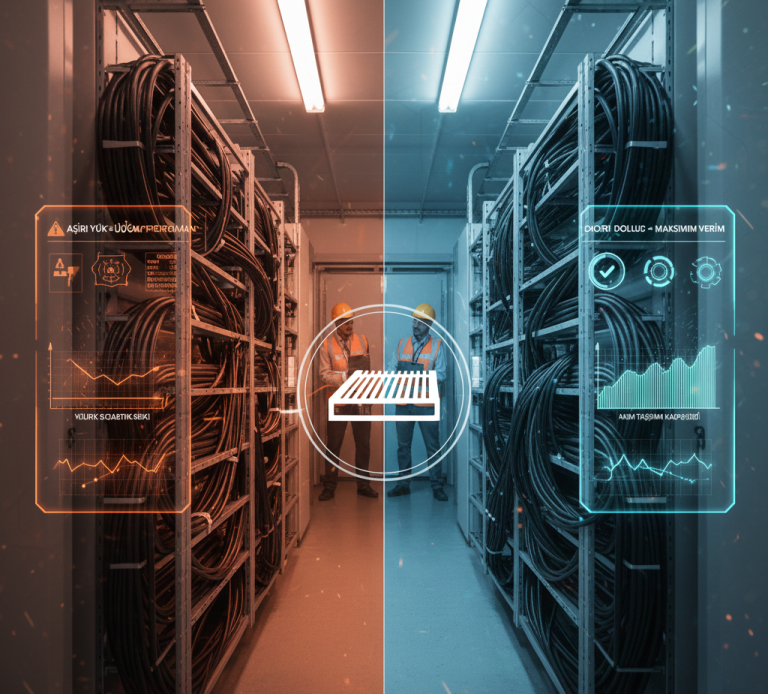

When industrial cybersecurity is mentioned, firewalls, network segmentation, software updates, and monitoring systems usually come to mind. However, many outages, data losses, and security incidents experienced in industrial facilities originate not from software, but from the physical infrastructure—specifically, cabling systems. The primary reason for this is that industrial environments are far harsher, more complex, and more variable than typical office networks.

High electromagnetic noise, vibration, temperature fluctuations, humidity, chemical vapors, and the risk of physical interference directly affect the cables used in industrial networks. When the right products are not selected or the infrastructure is not planned holistically, data transmission becomes unstable. Unstable data transmission is not merely a performance issue; it also represents a cybersecurity vulnerability.

A momentary data loss on a production line can cause PLCs to receive incorrect commands, sensor data to be misinterpreted, and cascading system shutdowns. These scenarios do not always result from malicious attacks; however, when the infrastructure is weak, such gaps provide an ideal foundation for hostile interventions.

What Does Industrial Cyber Resilience Mean?

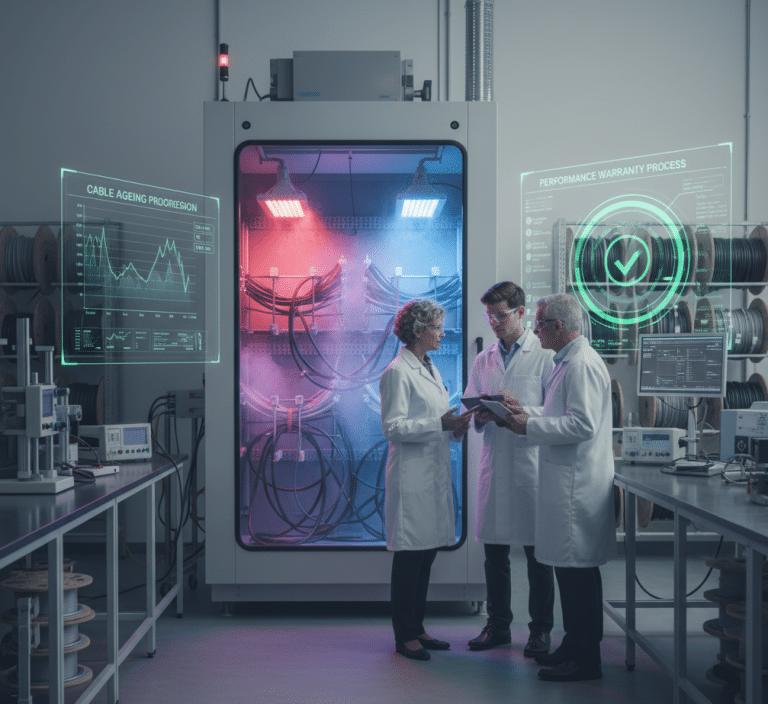

Industrial cyber resilience is not only the ability to prevent attacks, but also the capacity of a system to continue operating during attacks, failures, or unexpected conditions, to recover quickly, and to maintain data integrity. At this point, cabling infrastructure plays a decisive role.

A robust cabling infrastructure forms the lowest layer of the industrial network. The more stable this layer is, the more effective the security measures applied at higher layers become. Conversely, if the physical infrastructure is weak, software-based security solutions can provide only temporary protection.

For example, cables that are insufficiently protected against electromagnetic interference can cause corruption in data packets. While these issues may initially appear as simple communication errors, over time they can lead to false alarms in network monitoring systems, overlooked real threats, or unnecessary system shutdowns. This directly weakens cyber resilience.

Critical Differences Between Industrial Cabling and Office Networks

Unlike office networks, cabling infrastructure in industrial facilities does more than transmit data; it also ensures physical security, continuity, and operational stability. Therefore, infrastructure planning must take into account not only current requirements but also future expansion, digitalization, and evolving cyber threat scenarios.

A common mistake in many facilities is treating cabling infrastructure as a “completed” element once a project ends. In reality, industrial systems are living environments: production lines change, new machines are added, and network topologies expand. A small mistake made during initial installation can turn into serious security and performance issues in the years that follow.

At this stage, factors such as cable type, shielding structure, fire resistance, and suitability for environmental conditions directly affect cyber resilience. An incorrectly selected cable is more vulnerable to physical damage and therefore more susceptible to unauthorized intervention.

Physical Access and Infrastructure Security

The contribution of cabling infrastructure to cyber resilience in industrial networks is not limited to technical specifications alone. Physical access control is also a crucial part of the equation. Exposed, unlabeled, or poorly organized cables complicate maintenance processes and make malicious interference easier.

A structured and standards-compliant cabling infrastructure makes it easier to detect unauthorized access. Abnormalities along a line can be identified quickly, reducing response time. This strengthens one of the most critical elements of industrial cyber resilience: rapid recovery capability.

The Relationship Between Standards and Physical Infrastructure

An examination of industrial cybersecurity standards shows that physical infrastructure, even if indirectly, always plays an important role. While standards typically focus on network segmentation, access control, and monitoring, these mechanisms require a reliable physical layer to function effectively.

In a facility with weak cabling infrastructure, network segmentation may be theoretically perfect; however, signal degradation and connection losses in practice can cause unexpected communication issues between segments. This creates serious risks for both security and operational continuity.

An Infrastructure Approach for Sustainable Cyber Resilience

To ensure sustainable cyber resilience in industrial facilities, cabling infrastructure must be treated as part of a holistic strategy. The infrastructure should be planned, implemented, and regularly audited through a shared understanding among IT, OT, maintenance, and security teams.

When this approach is adopted, cabling infrastructure ceases to be a mere technical detail and becomes a cornerstone of the organization’s risk management, production continuity, and digital transformation goals. Especially with the rise of Industry 4.0, smart factories, and remote monitoring systems, the contribution of infrastructure to cyber resilience has become even more critical.

Conclusion: Resilient Cybersecurity Starts with Infrastructure

In conclusion, cabling infrastructure is one of the most important yet least discussed factors determining industrial cyber resilience. A robust, standards-compliant, and future-oriented infrastructure acts as an invisible shield against cyber threats. A weak infrastructure, however, can undermine even the strongest digital security investments.

For this reason, discussions about cybersecurity in industrial facilities must begin with the physical infrastructure. True resilience is only possible when the lowest layer is solid.

Frequently Asked Questions

Does cabling infrastructure really affect industrial cybersecurity?

Yes. In industrial systems, the physical layer where data transmission takes place is the cabling infrastructure. Weaknesses at this layer can compromise data integrity, cause communication disruptions, and reduce the effectiveness of cybersecurity measures. A robust infrastructure forms the foundation of cyber resilience.

What is the difference between industrial cabling and office network cabling?

Industrial cabling is designed to withstand harsh conditions such as electromagnetic interference, temperature fluctuations, humidity, vibration, and physical impact. Office-type network cabling is not suitable for these environments and can create security and continuity risks in industrial facilities.

How does poor cabling infrastructure create opportunities for cyberattacks?

Weak or poorly organized cabling can lead to signal degradation, unexpected connection losses, and uncontrolled access points. This makes systems harder to monitor and creates physical opportunities for malicious interference.

Can industrial cyber resilience be achieved through software alone?

No. While software-based security solutions are essential, they are not sufficient if the physical infrastructure is weak. Cyber resilience is achieved through the combined effectiveness of physical, network, and application layers.

How does cabling infrastructure affect system continuity?

A properly planned cabling infrastructure ensures stable data transmission and reduces unexpected outages. This helps prevent production stoppages, enables faster response to failures, and preserves operational continuity.

Why is physical access considered part of cybersecurity in industrial facilities?

Unauthorized physical access is one of the weakest links in the cybersecurity chain. Exposed or poorly organized cabling makes both intentional tampering and unnoticed changes easier. A structured and controlled infrastructure significantly reduces this risk.

Is cabling infrastructure a long-term cybersecurity investment?

Yes. A properly implemented infrastructure from the start significantly reduces future security vulnerabilities, system downtime, and additional costs. For this reason, cabling infrastructure should be considered a strategic, long-term investment rather than a short-term expense.

How do Industry 4.0 and digitalization affect cabling infrastructure?

Smart factories and connected systems require higher data volumes and more sensitive communication. This makes cabling infrastructure increasingly critical in terms of both performance and security.

How often should industrial cabling infrastructure be reviewed?

Depending on the size of the facility and the intensity of operations, the infrastructure should be audited at regular intervals. The addition of new equipment, changes in production lines, or frequent communication issues indicate that the infrastructure should be reassessed.