Industrial electrical systems are one of the most critical infrastructure elements for a business’s efficiency, safety, and long-term sustainability. Proper design, implementation, and management of these systems prevent operational disruptions for businesses. Here are 5 key points to consider in industrial electrical systems and why these processes are important:

- Accurate Power Capacity Calculation

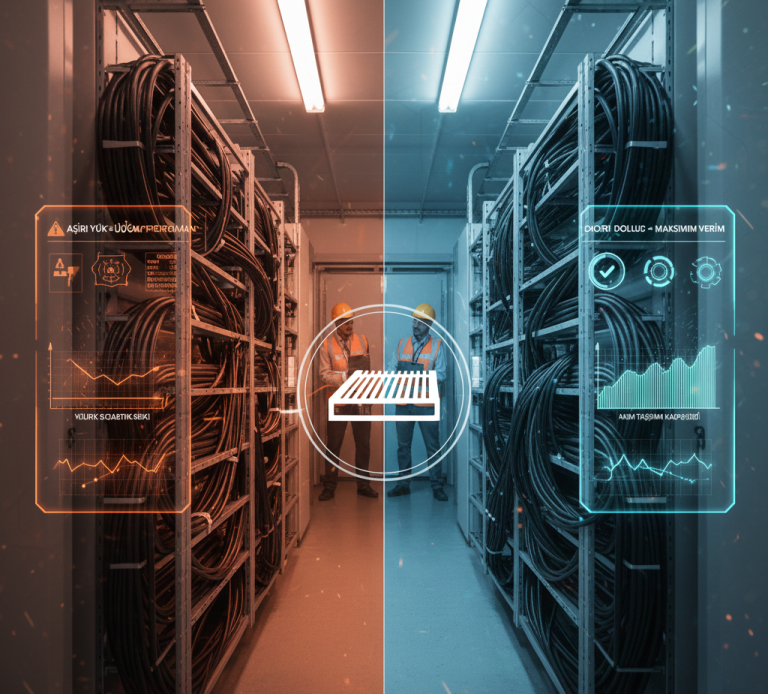

The energy needs of each business vary depending on the scale and scope of its operations. The capacity of the electrical system must be calculated to meet not only current loads but also potential future expansions. This ensures not only the reliable operation of equipment but also prevents higher costs in the long run. Insufficient power capacity can lead to overloads, energy loss, and serious malfunctions.

A power analysis conducted by an expert team ensures the system is designed in a balanced manner and eliminates the risk of overload. Accurate power capacity calculation is a critical step for both economic and operational sustainability. - Selection of Quality Equipment and Materials

The quality of equipment used in industrial electrical systems determines the overall performance of the system. Low-quality equipment can lead to frequent failures, disrupting business operations and increasing maintenance costs. Therefore, sourcing high-quality, certified products from reliable suppliers is crucial.

Quality materials not only enhance durability but also improve energy efficiency and reduce operational costs. Products compliant with international standards are ideal for both safety and performance. - Proper Wiring and Insulation

Correct installation of electrical cables is one of the cornerstones of a long-lasting system. Incorrect wiring or inadequate insulation can lead to serious safety risks. For example, a fault in cable insulation can increase the risk of fire or cause energy loss in the system.

In industrial environments, high-performance cables and insulation materials resistant to external factors should be preferred. These materials enhance system reliability and minimize the risk of failure under harsh working conditions. - Regular Maintenance and Periodic Inspections

Regular maintenance of electrical systems ensures that small issues are detected before they escalate and extends the system’s lifespan in the long run. Periodic inspections allow for timely replacement of worn or damaged equipment and prevent operational disruptions.

Professional service providers like Delta Tema Elektrik regularly audit your systems to detect potential failures in advance. This not only enhances safety but also eliminates costly downtime. - Energy Efficiency and Environmental Sensitivity

Energy costs account for a significant portion of business budgets. Therefore, designing industrial electrical systems to improve energy efficiency provides a major advantage. Devices and systems that consume less energy increase environmental sensitivity and reduce operational costs.

Additionally, integrating energy management systems facilitates monitoring and optimizing consumption. This ensures both environmental sustainability and long-term cost savings.

Industrial electrical systems, when designed and implemented correctly, provide businesses with a safe, efficient, and sustainable infrastructure. The critical points mentioned above form the foundation for the healthy operation of these systems. By partnering with an expert like Delta Tema Elektrik, you can receive professional support at every stage of your projects and ensure long-term success.

For professional guidance and high-quality products in these processes, visit the Delta Tema Elektrik website.