Armored power cables are a special type of cable used to ensure safe electrical transmission, especially in harsh environmental conditions. They exhibit high resistance to mechanical impacts and external factors. From the construction sector to power plants, infrastructure projects to industrial facilities, these cables play a critical role in the reliability of systems.

In this article, we will provide comprehensive information about armored power cables, covering all the details under headings such as technical specifications, areas of use, advantages, and selection criteria.

What are Armored Power Cables?

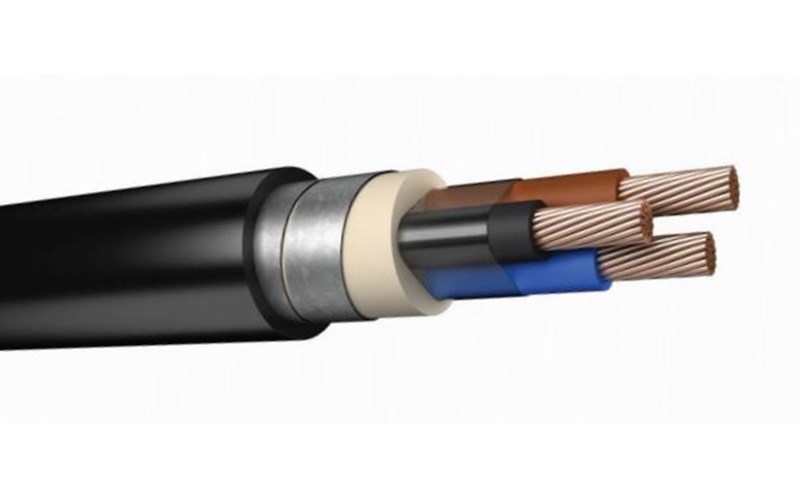

Armored power cables are energy transmission cables strengthened with a metal armor layer placed around the conductive structures. This armor is usually made of steel tape (STA), steel wire (SWA), or aluminum alloys, and it increases the cable’s resistance to both mechanical and chemical external factors.

In addition to the armor layer, insulation and outer sheath layers are typically made of materials such as PVC and XLPE. Thus, the cable provides superior protection against many risk factors such as moisture, impact, abrasion, and chemical vapors.

In Which Areas are Armored Power Cables Used?

Armored power cables are widely preferred in many different sectors. The main areas where these cables are used include:

- Underground power transmission lines

- Industrial facilities and in-plant distribution systems

- Tunnel and metro projects

- Power plants and switchyards

- Ships, ports, and offshore platforms

- Buildings with high fire risk and emergency escape routes

These areas of use demonstrate the wide range in which armored power cables are considered.

Technical Specifications of Armored Power Cables

Armored power cables are notable not only for their structural durability but also for their various technical specifications. Thanks to these features, they are safely preferred in many challenging application areas.

- Conductor Structure: Usually, copper or aluminum conductors are used. Copper is preferred in systems carrying high current due to its higher conductivity.

- Insulation Material: PVC, XLPE, or halogen-free insulation options are available for armored power cables.

- Armor Type: Steel tape or steel wire armor options vary depending on the area of use.

- Outer Sheath: UV-resistant, moisture-resistant, and chemical-resistant special outer sheaths are preferred.

- Flame Retardant Properties: LSZH sheaths that reduce smoke emission in case of fire can be used.

Thanks to these technical specifications, armored power cables can operate safely for many years, both indoors and outdoors.

Advantages of Armored Power Cables

Armored power cables offer many advantages not only in terms of durability but also in terms of safety, sustainability, and longevity:

- Mechanical Protection: Continues to operate without being affected by physical impacts.

- Resistance to External Factors: Resistant to elements such as moisture, salt water, and chemical vapors.

- Fire Resistance: Halogen-free structures prevent the release of toxic gases in case of fire.

- Protection Against Rodents: Especially in underground cables, the gnawing of the cable by animals such as mice is prevented.

- Prevention of Power Outages: The likelihood of system failure is reduced, increasing operational continuity.

These advantages clearly show why armored power cables are so widely preferred in both industrial facilities and modern urban infrastructures.

What Should Be Considered When Choosing Armored Power Cables?

Choosing the right cable directly affects both safety and system performance in the long run. The main criteria to consider when selecting armored cables are:

- Application Area: Indoor, outdoor, or underground? Each environment has different needs.

- Armor Type: Should tape or wire be used? Wire armor offers higher mechanical resistance.

- Cross-Section and Current Carrying Capacity: A cross-section suitable for the energy requirement should be selected.

- Temperature Range: A cable suitable for the ambient temperature should be preferred.

- Compliance with Standards: Compliance with national and international standards such as IEC, TSE, and VDE should be sought.

Ensuring correct engineering calculations during the selection process ensures the smooth operation of the system.

Armored Power Cables and Sustainability

In today’s world, not only robustness but also environmental compatibility and sustainability have become decisive factors in energy infrastructures. Armored cables, thanks to their long-lasting structures, eliminate the need for frequent replacement, which contributes to the reduction of production waste and carbon footprint.

In addition, models produced with halogen-free outer sheaths minimize the release of gases that can harm the environment in case of fire.

Conclusion: Reliable Solution in Energy Transmission with Armored Power Cables

Armored power cables have become indispensable in modern energy transmission systems with both their superior performance in harsh field conditions and their long-lasting and safe structures. Using the right armored cable in the right project forms the basis of a safe and sustainable infrastructure not only today but also in the long term.