The Correct Filling Ratio in Cable Carrying Systems: How Does It Affect Current Carrying Capacity?

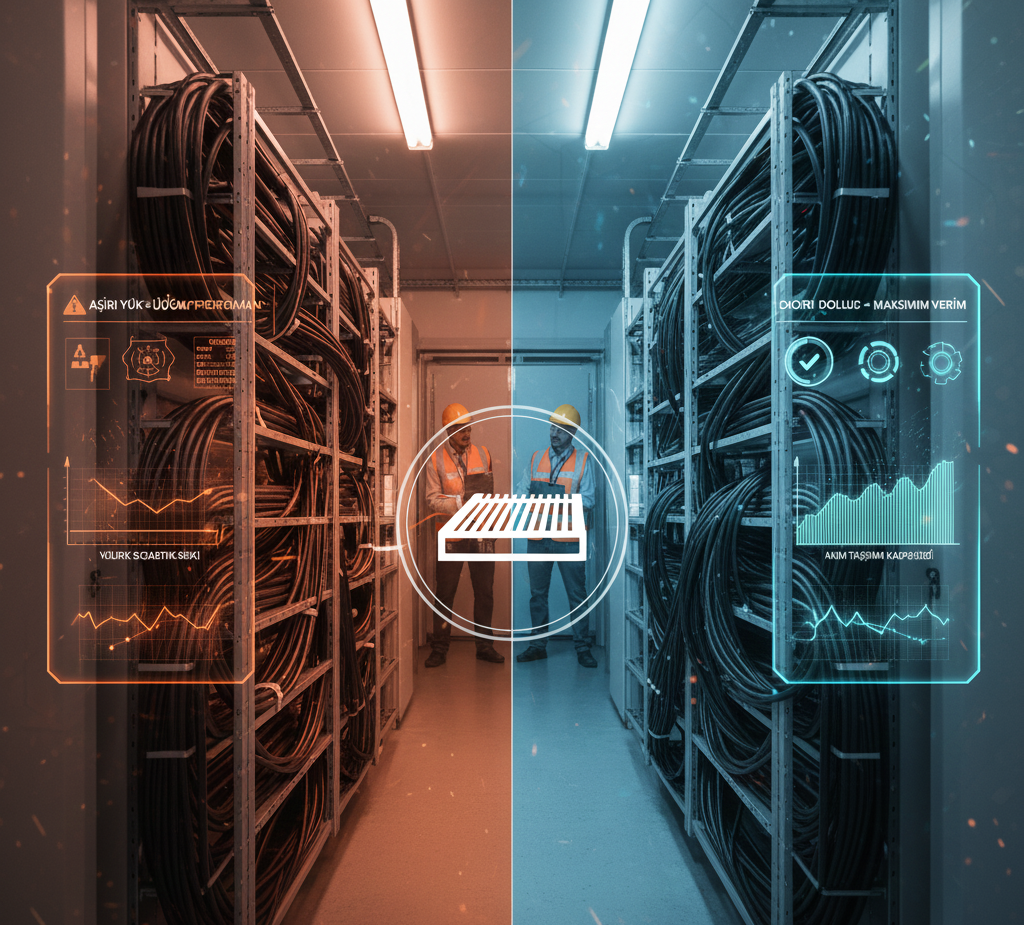

The Correct Filling Ratio in Cable Carrying Systems is one of the most critical planning parameters for the reliability, efficiency, and longevity of an electrical installation. One of the most common mistakes made to cut project costs is overcrowding cable trays (ladder or channel systems). This overcrowding hinders air circulation around the cables and initiates thermal runaway, seriously reducing the cable’s nominal current carrying capacity. This reduction (derating) shortens the cable’s lifespan and increases the fire risk. The correct use of systems like STS Cable Trays plays a vital role in preventing these risks.

In this comprehensive technical guide, we will examine the thermal effects of The Correct Filling Ratio in Cable Carrying Systems, the derating factors according to international standards (IEC/TSE), and how to protect the quality of Prysmian and 2M Kablo throughout the life of your installation.

Thermal Fundamentals of Current Carrying Capacity

A cable’s nominal current carrying capacity is determined in a way that prevents the conductor from reaching the maximum safe operating temperature (e.g., 90°C for XLPE or 70°C for PVC).

- Joule Loss ($I^2R$): When current passes through the cable, energy is dissipated as heat due to the conductor’s resistance. This heat must be transferred to the surrounding environment by the cable’s insulation material.

- Thermal Runaway: If heat transfer to the environment is insufficient, the cable temperature rises. As the temperature increases, resistance increases, which generates more heat. This cycle leads to rapid degradation of the insulation and ultimately cable failure, jeopardizing the long-term investment.

The Derating Effect of the Filling Ratio on Capacity

Cables cool down by radiating the heat they carry into the surrounding air and the structure of the cable carrying system. However, the closer the cables are laid together, the less surface area is in contact with cool air.

Grouping Factor (IEC 60364 and TS HD 60364-5-52)

International standards determine a derating factor (Grouping Factor) that must be applied based on the number of cables laid side-by-side in a cable tray. You can access detailed technical information about these factors via the IEC 60364-5-52 standard.

| Number of Cables | Derating Factor (Approximate) |

| 1 | 1.00 |

| 3 | 0.70 |

| 6 | 0.54 |

| 10 | 0.45 |

According to this table, for six cables laid side-by-side, each cable can safely carry only about half of its nominal capacity. This means that both the cost and safety of the installation are doubly compromised.

Why is Air Circulation Vital?

Ensuring The Correct Filling Ratio in Cable Carrying Systems guarantees adequate air circulation around the cables. Overcrowding trays creates pockets of hot air called “boundary layers” around the cables. These hot spots rapidly age the cable insulation in that region. Preferring perforated tray systems like STS Cable Trays reduces thermal risk because they allow vertical and horizontal airflow.

Practical Application and Maximum Filling Limits

In engineering practices, a filling ratio of 40% to 50% is generally recommended for The Correct Filling Ratio in Cable Carrying Systems.

- Cross-Sectional Area Calculation: The ratio of the total cross-sectional area of the cables to the usable cross-sectional area of the tray should be considered, not just the tray’s width. While this ratio can be slightly higher for control and signal cables, not exceeding 40% for main power cables is a safety standard.

Correct Planning is Long-Term Investment: Failing to account for the derating factor either necessitates using larger cross-section (expensive) cable or results in the system operating unsafely.

Project Safety with Deltatema

Deltatema prioritizes thermal safety from the very beginning of your project in the supply of carrying systems like STS Cable Trays.

- Integrated Supply: We provide technical support for carrying system selection and capacity calculations so that you can fully utilize the nominal values of the high-quality Prysmian and 2M Kablo products we supply (especially MV cables like N2XSY). You can find more information about the derating factors included in the Prysmian Technical Guide through these technical articles.

- Quality Guarantee: The only way to preserve the lifespan of Prysmian and 2M Kablo‘s insulation materials (XLPE, HFFR) is to apply standard-compliant installation and The Correct Filling Ratio in Cable Carrying Systems. All components supporting this integrated approach are available in our product range.

Conclusion

Maintaining The Correct Filling Ratio in Cable Carrying Systems is not about cost savings, but about thermal safety and long-term investment in critical infrastructure projects. Correct planning accounts for derating factors and prevents the current carrying capacity from being compromised.