Introduction: An Investment in Efficiency Beyond the Initial Cost

In large-scale projects such as industrial facilities, commercial buildings, and data centers, the proportion of cable support systems within the total cost of the electrical installation is often either overlooked or evaluated solely based on material price. However, the choice between cable support systems—specifically the wire mesh tray (or basket tray) and the sheet metal tray (perforated/solid cable tray)—directly influences the Total Project Cost (TPC), installation time, and maintenance expenses over the entire operational life.

As Delta Tema Elektrik, offering world-class solutions from manufacturers like OBO Bettermann, we recommend looking beyond the initial investment cost for cable support systems. In this comprehensive analysis, we will detail the cost and efficiency differences between the two most commonly used systems, the wire mesh tray and the sheet metal tray, to help you make the most informed decision for your projects. Our focus will be not only on the material cost but also on labor, assembly speed, and long-term operating expenses.

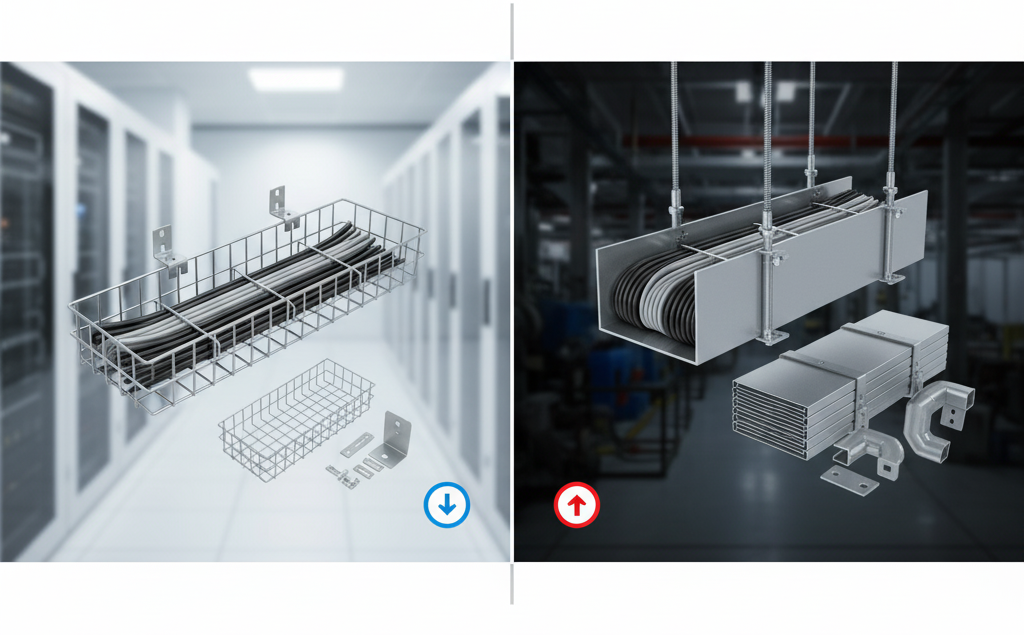

I. Wire Mesh Tray Systems: The Advantage of Speed and Flexibility

The wire mesh tray, also known as the cable basket or wire basket, has rapidly gained popularity in modern installations due to its open structure made of welded steel wires. Products featuring patented quick-connection systems, such as the OBO Bettermann GR-Magic series, provide overwhelming superiority over sheet metal trays in terms of assembly time.

A. Impact on Labor Cost (The Most Critical Factor)

The greatest cost advantage of wire mesh tray systems lies in labor.

- Rapid Assembly: Wire mesh trays are often joined using snap-on lock systems (like OBO Bettermann GR-Magic) that do not require bolts and nuts. This can reduce the assembly time per linear meter by 30% to 50% compared to sheet metal tray systems.

- Flexible Shaping: Corners, T-junctions, or level changes can be easily created on-site using wire cutters. Sheet metal trays require expensive and pre-planned specialized fittings (elbows, tees, reducers) for these types of transitions. With wire mesh trays, the cost of fittings is nearly zeroed out.

B. Contribution to Thermal Management and Cable Lifespan

The open structure of the wire mesh tray maximizes airflow around the cables. This leads to:

- Thermal Management: It prevents cable overheating. Overheating causes energy losses and shortens the life of the cable insulation.

- Energy Efficiency: The extended cable lifespan and reduced energy losses translate into significant reductions in long-term operational costs.

External Link: For more in-depth information on international electrical standards, such as those defined in IEC 60364-5-52, which governs the current-carrying capacity of cables and how managing temperature and heat dissipation (crucial in cable tray selection) impacts energy efficiency, please consult this external resource:https://www.iec.ch/

II. Sheet Metal Tray Systems: The Factor of Durability and Protection

Traditional sheet metal tray systems are generally manufactured from steel with a solid, perforated, or continuous bottom surface. They remain indispensable for high mechanical strength and fully enclosed applications.

A. Advantages in Material Cost and Protection

The benefits of the sheet metal tray emerge especially under heavy-duty conditions:

- Mechanical Protection: Fully enclosed or thick-gauge sheet metal trays better protect cables against physical damage (falling objects, impact).

- Visual Aesthetics: Solid bottom sheet metal trays may be preferred in office or commercial areas for cable concealment and aesthetic integrity.

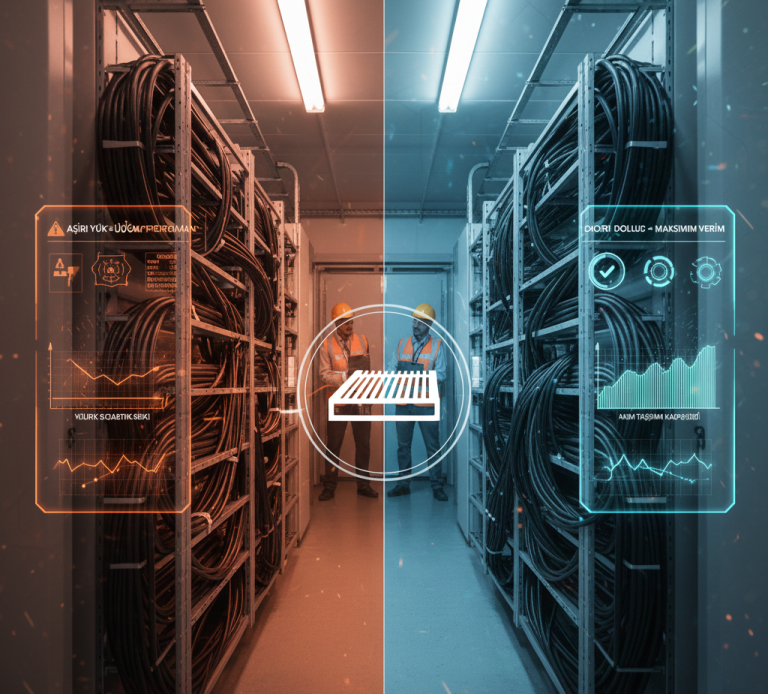

B. Hidden Costs: Maintenance and Revision

The initial material cost of sheet metal tray systems can sometimes be lower than wire mesh (especially when thin, low-quality sheet metal is used). However, the real cost emerges during the installation and operation phase:

- High Labor: Bolting together special elbows and transition pieces is time-consuming and extends the labor duration.

- Difficulty of Maintenance: The closed structure makes fault detection and cable revision difficult. To add or remove cables, the cover must be completely opened, which increases maintenance time and, consequently, labor costs.

- Weight: Sheet metal trays are heavier than wire mesh trays. This requires more numerous and stronger supports and suspension elements, indirectly increasing material and assembly costs.

III. Total Project Cost (TPC) Impact Analysis

The impact of cable support systems on the Total Project Cost (TPC) is understood by evaluating the following three main components:

| Component | Wire Mesh Tray (Basket Tray) | Sheet Metal Tray (Cable Tray) | TPC Impact |

| Material (Initial Investment) | Medium – High (Stainless steel options common) | Low – Medium (Depends on quality) | Wire mesh material cost can be slightly higher. |

| Installation Labor | Very Low (Quick connection, flexible cutting) | High (Bolting, requirement for specific fittings) | Wire mesh significantly reduces TPC here. |

| Operation/Maintenance | Low (Easy visual inspection, fast cable addition) | High (Closed structure, difficult revision, potential cable heating) | Wire mesh provides an increase in long-term efficiency. |

Conclusion: Material price alone is not the determining factor. The total cost of a cable support system in a project can be comprised of 60-70% labor. Therefore, systems like the wire mesh tray, which offer rapid installation, are often a more economical and rational solution in terms of Total Project Cost, even if their initial material costs are slightly higher.

External Link: For technical insights and best practice guides on cable ladder and cable tray systems, including considerations for material type, loading, and installation methods that directly influence efficiency and TPC in large-scale projects, you can consult this external resource from a leading electrical industry association:https://www.theiet.org/

Conclusion: A Sound Engineering Decision

When deciding between a wire mesh tray vs. sheet metal tray for your project, do not merely look at the material weight per square meter. Calculate how much the system reduces labor costs, how much it shortens the assembly time, and how much it increases the thermal efficiency of the cables. The innovative wire mesh tray systems from OBO Bettermann, offered by Delta Tema Elektrik, optimize not only the present but also the future operation and maintenance processes of your project.

Contact us immediately for the most suitable, highly efficient, and lowest TPC-offering cable support solutions for your project. Delta Tema Elektrik Contact Page Link