Cable Termination and Joint Kits are the most sensitive and critical components of medium and high voltage (MV/HV) energy transmission systems. Regardless of its quality, a cable’s performance is limited by the quality of insulation at its joints and terminations. These connection points are where the cable is most exposed to the electric field, moisture, and mechanical stress; thus, the reliability of these points directly determines the long-term investment value of the entire system. Prysmian, a world leader in cable technology, reinforces this position with advanced Cable Termination and Joint Kits that secure the cable’s lifespan.

In this comprehensive guide, we will examine the vital importance of Cable Termination and Joint Kits in system integrity, Prysmian’s pioneering cold- and heat-shrink technologies, and how Deltatema guarantees your projects in this field that requires specialized expertise.

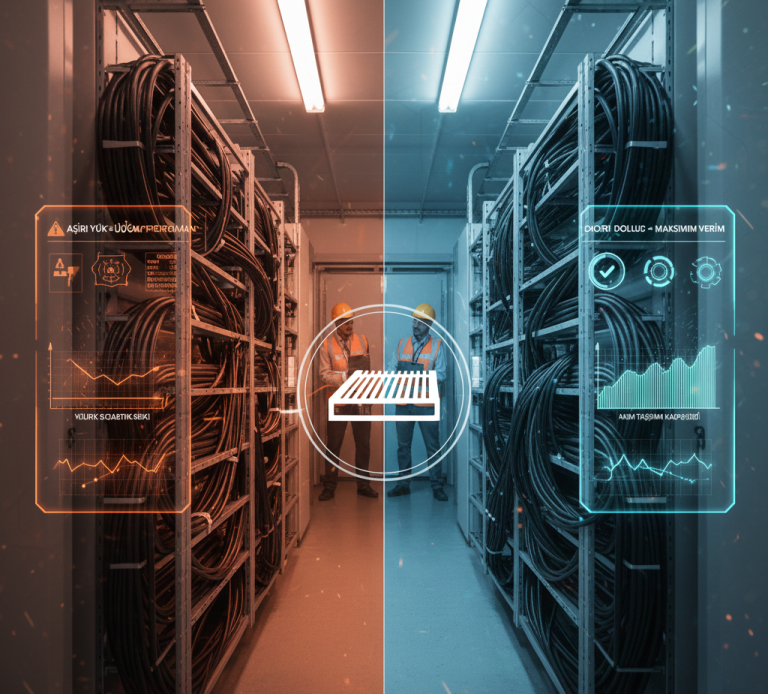

The Importance of Termination and Joint in System Integrity

When an MV/HV cable fails, approximately 80% of these failures occur at the joint or termination kits. The main reason is that the cable’s uniform structure is compromised at these points.

- Electrical Stress Management: The cable’s outer conductor (screen) is cut at the termination point. This causes the electric field to abruptly end, leading to a concentration of electrical stress at the joints. Prysmian accessories include stress control elements to help distribute this tension.

- Moisture Protection: In cables used underground or in damp environments, water ingress into the insulation (“water treeing”) is the greatest danger. Quality Cable Termination and Joint Kits provide a complete, waterproof seal against moisture entry.

- Thermal Harmony: During the heating and cooling of the cable in normal operation, the joint material must expand and contract at the same rate as the cable. Prysmian’s materials, compatible with XLPE and EPR insulation, ensure this thermal harmony.

Prysmian’s Pioneering Technologies: Heat and Cold Shrink

The core technologies used in Prysmian’s Cable Termination and Joint Kits offer ease of installation on-site and superior insulation performance:

Heat-Shrink Technology

In this traditional and reliable method, the tubes and sleeves making up the kit are heated with a heat gun and shrink tightly onto the cable.

- Advantages: Provides a permanent and completely waterproof seal, highly reliable for underground applications and industrial environments exposed to severe chemical and mechanical stress.

- Areas of Application: Chemical plants and heavy industry sites.

Cold-Shrink Technology

Prysmian’s innovative cold-shrink technology is made from an elastomeric material based on silicone or EPR and comes pre-stretched.

- Advantages: Installation is done without the need for a heat gun. This increases safety and significantly shortens the assembly time, especially in confined spaces (switchgear facilities), areas with flammable gases, and tunnels.

- Areas of Application: MV/HV switchyards and urban energy distribution networks.

Product Codes Used in MV/HV Cables and Application

Cable Termination and Joint Kits must be selected specifically according to the voltage level, conductor count, and insulation material (XLPE, EPR) of the cable.

- Prysmian’s TEE / Termination Kits: Prysmian’s MTC (Medium Tension Connection) series offers both heat-shrink and cold-shrink joint kits. These kits include semiconducting and stress control elements that assist in managing the dielectric stress of the cable’s insulation.

- Incompatibility Risk: The lack of chemical and thermal compatibility between the accessory kit used and the cable’s XLPE insulation is the primary cause of failure. Brands like Prysmian and 2M Kablo guarantee this compatibility.

Deltatema Expertise and Project Assurance

The correct selection and assembly of Cable Termination and Joint Kits require technical expertise, as much as the cable itself. At Deltatema, we do not just supply products; we also guarantee the quality of this process.

- Training and Certification: Our expert team ensures you apply the highest standards in the assembly of joint kits by following Prysmian’s on-site training.

- Holistic Solution: We supply the joint kits appropriate for the 2M Kablo or Prysmian brand cables used in your project (e.g., 2M Kablo products), guaranteeing that your entire system is compatible and secure.

Conclusion

Cable Termination and Joint Kits are the most important area of application for your long-term investment philosophy. Make the weakest point of your projects the strongest by choosing accessories equipped with Prysmian’s heat- and cold-shrink technologies. At Deltatema, we are proud to offer you this comprehensive safety.