Cables Resistant to Harsh Conditions offer features far beyond standard electrical cables, being essential for the continuity and safety of projects in environments like mining, tunnel construction, and heavy industrial installations. These environments continuously expose cables to corrosive chemicals, water, mechanical impacts, and high vibrations. In such critical infrastructure projects, a cable failure means not only a costly repair but also vital hazards and long operational downtime. Therefore, specialized cable solutions developed by global experts like Prysmian Group constitute the foundation of long-term investment.

In this comprehensive guide, we will examine the technical requirements that Cables Resistant to Harsh Conditions must meet, Prysmian‘s innovative solutions in this field, and how, at Deltatema, we offer a guarantee for your projects.

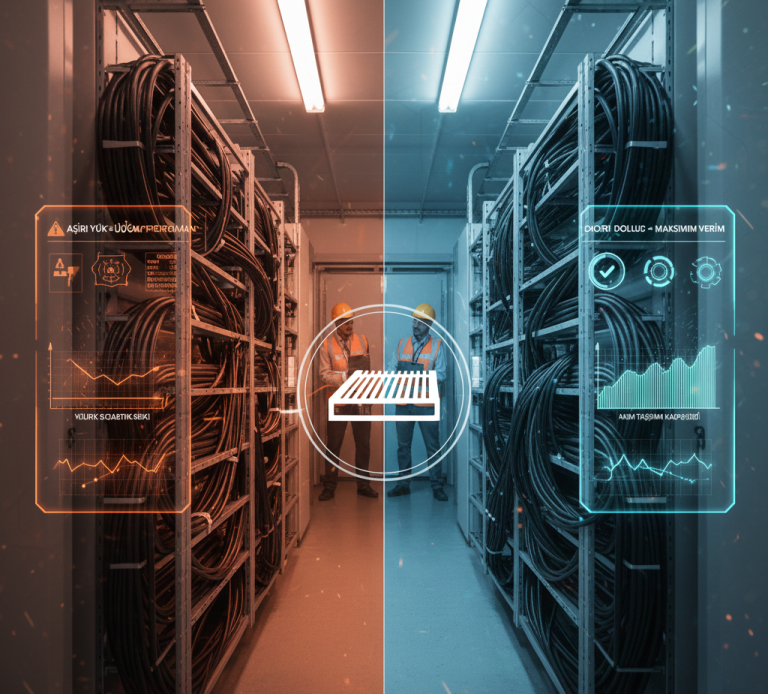

Impacts of Mining and Tunnel Environments on Cable Systems

Mines and tunnels are the most challenging environments that test the durability of cables. Cables here must withstand these specific stress factors:

- Mechanical Abrasion: The movement of heavy machinery, sharp rock fragments, and vibration cause continuous wear on the outer sheath and armor.

- Chemical and Moisture Effects: Mine waters, chemical solutions, and constantly high humidity levels lead to the rapid degradation of insulation (known as “water treeing”).

- Fire and Gas Risk: The presence of flammable gases like methane in closed tunnels and mine shafts, and the difficulty of evacuation in case of fire, make the use of halogen-free cable vital.

Prysmian’s Solution Technologies: The Balance of Toughness and Flexibility

Prysmian Group overcomes these challenges with specialized cables developed for mining and heavy industry. The brand offers solutions that combine high mechanical protection with operational flexibility.

High Mechanical Protection and Armor Structures

- Steel Wire Armor (SWA / YVŞV): Steel wire armor is used for cables laid directly underground or exposed to rock fragments. This armor provides superior protection against external impacts and tensile forces, preserving the cable’s transmission integrity.

- PUR/EPR Outer Sheaths: For cables designed for mobile systems (cranes, conveyors, drums), outer sheaths based on Polyurethane (PUR) or Ethylene Propylene Rubber (EPR) are used instead of PVC. These materials are far superior to PVC in resistance to oil, chemicals, and bending stress.

Fire and Gas Safety

The most important requirement for tunnels is that the cable maintains critical systems operational in case of fire.

- NHXH FE180/E90 (Functional Integrity): These Prysmian cables ensure that critical systems (such as emergency lighting and smoke extraction systems) continue to function for up to 180 minutes even under fire. This is the pinnacle of fire-resistant cable technology.

- AFUMEX (HFFR): Produced with Halogen-Free (HFFR) components, which prevent the emission of toxic gases and dense smoke in closed areas.

Application Areas and Featured Product Codes

The applications of Cables Resistant to Harsh Conditions are addressed by Prysmian’s wide product range:

- Mining and Tunnel Cables: Heavy-duty, flexible cables like the NTSCGÖU series are used to power submersible pumps and drilling machinery. Prysmian’s special mining cables are certified for safe operation in explosive and methane environments.

- Drum and Crane Cables: For mobile systems subject to continuous winding and unwinding, highly abrasion-resistant cables with rubber (EPR) insulation, such as the (N)SHTÖU series, are preferred.

- Marine and Ports: Port cranes and ship terminals require high-performance cables resistant to saltwater and UV rays.

Project Risk Management with Deltatema

The selection of Cables Resistant to Harsh Conditions requires more than just reading a product code in a catalog. The cable’s installation method, ambient temperature, and the type of mechanical stress it will be subjected to must be analyzed.

- Expert Supply: Deltatema supplies these niche and special cables from Prysmian directly, ensuring your project meets certification and quality requirements. You can check Prysmian’s technical documents with Deltatema’s assurance.

- Consulting: Our expert teams advise you on selecting the correct cable for your project, whether it requires fire-resistant cable or mechanical armor.

Conclusion

Cables Resistant to Harsh Conditions are the only guarantee of safety and long-term investment in projects like mining and heavy industry. Choosing the quality of Prysmian and 2M Kablo ensures that your cables will overcome not only today’s standards but also the challenges of the future. At Deltatema, we are with you with high-performance cable solutions suitable for every condition your project requires.