Electrical Partial Discharge Event

Electrical Partial Discharge Event is the most critical method used to prevent over 80% of the destructive failures that occur in High and Medium Voltage (HV/MV) electrical systems. The Electrical Partial Discharge Event (PD) is defined as a local electrical discharge that happens in a small area within the dielectric insulation system. These tiny sparks erode the insulation of the cable or equipment over time, eventually leading to a major dielectric breakdown and catastrophe. Therefore, Partial Discharge Fault Detection (the process of finding it) is the most important preventive maintenance strategy applied to guarantee the safety of your electrical assets and your long-term investment.

In this comprehensive guide, we will examine the Electrical Partial Discharge Event itself, the physical meaning of what is discharge, why it occurs, the advanced detection methods used in the industry, and how Deltatema controls this invisible enemy with the quality of global brands like Prysmian.

What is Partial Discharge (PD) and Why Does the Discharge Occur?

Partial Discharge Fault Detection, in simple terms, is the art of finding insulation defects. The occurrence of PD is rooted in irregularities in insulating materials and high electric field concentration. The core of the problem lies in the definition of a dielectric: a substance that conducts electricity poorly but supports electric fields well. Irregularities in these dielectric materials (XLPE, EPR, Paper) are the fundamental cause of the PD:

- Insulation Defects: Voids or bubbles trapped inside the insulation material during manufacturing. Since air’s dielectric strength is lower than solids like XLPE, these voids break down under electrical stress, causing a small discharge.

- Contaminants: Moisture, dust, or metallic impurities on the surface or within the insulation interrupt the normal current path, triggering the discharge.

- Design Defects: The lack of homogeneous electric field distribution at cable joints and terminations causes local field concentration and the formation of PD.

Types of PD and Levels of Danger

PD events are divided into three main types: Corona Discharge (radiating into the air), Surface Discharge (moving along the insulation surface), and Internal Discharge (the most dangerous type, occurring in voids within the insulation).

Partial Discharge Fault Detection Methods and Devices

Since PD emits various energy types (acoustic, electromagnetic, thermal), various advanced techniques are used for its detection. Early detection in high voltage cable and medium voltage lines prevents failures and the loss of long-term investment.

- Acoustic/Ultrasonic Method: Detects the sound energy emitted during the PD event (in ultrasonic frequencies above 20 kHz). Acoustic imaging cameras are used.

- Electrical and High Frequency (HFCT/UHF) Methods: The IEC 60270 standard defines the calibration for these methods. A partial discharge test device (like Megger or Fluke) is used to measure the high-frequency current pulses generated during PD. UHF sensors (300 MHz – 1.5 GHz) are used to measure PD signals, typically within the metal enclosures of switchgear facility cables.

Prysmian Quality and Preventive Solutions

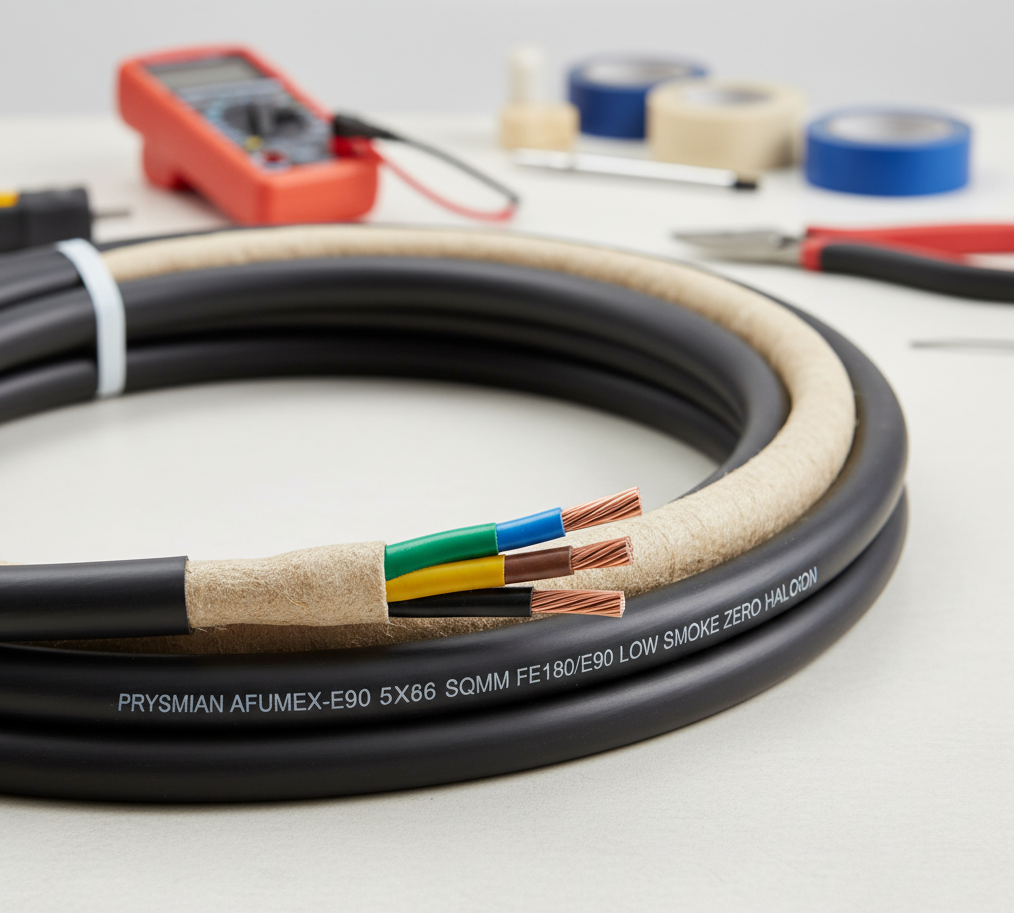

Partial Discharge Fault Detection begins with the quality of the cable. Brands like Prysmian minimize the risk of PD formation by using high-quality XLPE insulation and smooth semiconducting layers, which reduces the likelihood of electric field accumulation right from the manufacturing phase. This demonstrates Prysmian technical excellence.

- Online Monitoring: Manufacturers like Prysmian have developed systems that continuously monitor (online) PD levels with sensors permanently mounted on cable joints and terminations. This ensures constant tracking of the long-term investment.

- Deltatema Expertise: At Deltatema, we reduce the risk of PD from the start by selecting the correct High Voltage Cable and Types for your projects (e.g., the N2XSY cable series), and we support you with technical support for periodic monitoring.

Safety and Risk Management

Regardless of how accurately the cable current carrying capacities and cable cross-section are calculated, the risk of PD is always present. This risk must be reduced to zero in critical infrastructure projects (hospitals, data centers). Partial Discharge Fault Detection and monitoring systems allow maintenance teams to intervene before a failure occurs, preventing unplanned outages and disasters.

Conclusion

Partial Discharge Fault Detection is the future of your electrical systems. To achieve maximum safety and a long-term investment in your projects, it is imperative to take preventive measures with Prysmian quality. At Deltatema, we are proud to offer you not only products but a solution secured by Partial Discharge Fault Detection.

Deltatema’s Broad Project Expertise

Deltatema’s expertise is not limited to high-voltage fault detection. Our project consulting team is your solution partner in all types of complex electrical infrastructure. We provide support for the correct project and material selection in legal and bureaucratic processes, including the necessary steps for how to get an electricity subscription for agricultural land.

External Links and Resources

- Prysmian Technical Documentation: https://tr.prysmian.com/tr/medya/teknik-makaleler/kablo-izolasyon-malzemeleri (DoFollow)

- T.R. Ministry of Environment and Urbanization Legislation: https://www.csb.gov.tr/mevzuat (DoFollow)

- T.R. Ministry of Agriculture and Forestry Guide (Agricultural Subscription): https://www.tarimorman.gov.tr/TRGM/Duyuru/612/Tarimsal-Sulama-Elektrik-Aboneligine-Esas-Gorus-Verilmesi-Ve-Belge-Duzenlenmesi-Hakkinda-Yonerge-Duyurusu (DoFollow)