Fire-Resistant Cables (N2XH, NHXMH, N2XH FE 180): Understanding Standards and Their Critical Importance in Projects

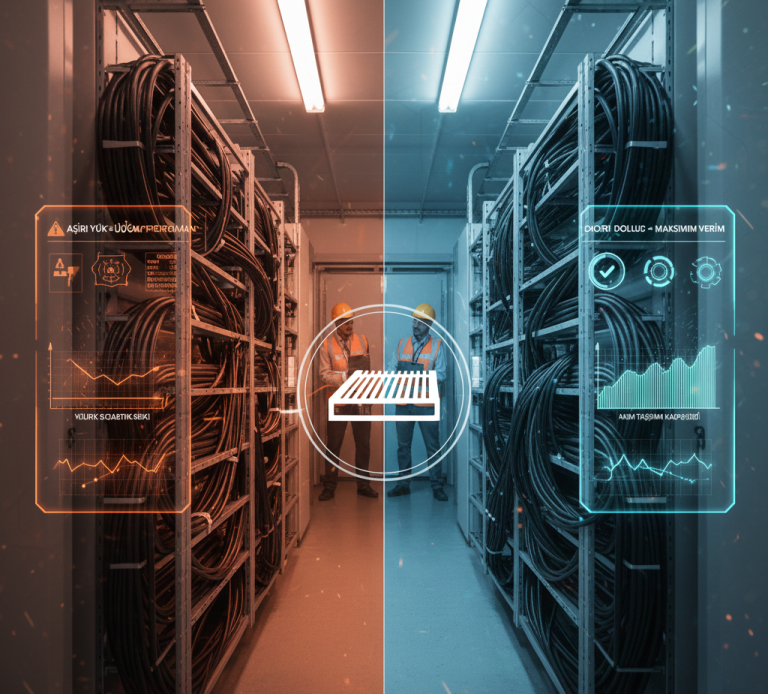

Modern buildings and industrial facilities are equipped with complex electrical systems. While the safe and uninterrupted operation of these systems is vital, emergencies like fires pose a serious threat. Standard cables spreading flames, emitting dense and toxic smoke, or causing critical systems to fail instantly during a fire present significant risks to life and property. This is where fire-resistant or fire safety cables come into play. Specifically, special cable types such as N2XH, NHXMH, and N2XH FE 180 are designed both to enhance life safety and maintain the operation of critical systems during a fire. So, what exactly are these cables, what standards do they adhere to, and why is their role in projects so critical?

Why Use Fire-Resistant Cables?

One of the greatest dangers in a fire situation is the rapid spread of flames and the dense smoke produced. When standard PVC (Polyvinyl Chloride) insulated cables burn, they release dense black smoke and toxic, corrosive gases like hydrochloric acid. This situation obstructs visibility on escape routes, causes panic, irritates the respiratory system, and damages electronic equipment. Furthermore, standard cables can easily conduct flames, causing the fire to spread rapidly to other parts of the building.

Fire-resistant cables, however, are manufactured with special materials to minimize these risks. Their main benefits include:

- Flame Retardancy: They slow down the progression of fire along the cable, limiting its spread.

- Low Smoke Density: They emit less smoke during a fire, increasing visibility and facilitating evacuation.

- Halogen-Free / Zero Halogen: They do not release toxic and corrosive gases (halogens like chlorine, fluorine, bromine) when burning, reducing harm to human health and equipment.

- Circuit Integrity: Some special types (FE series) continue to conduct electricity for a specified period (e.g., 180 minutes) during a fire, ensuring the operation of emergency systems.

Thanks to these features, fire safety cables play a vital role, especially in hospitals, schools, shopping centers, tunnels, subways, data centers, high-rise buildings, and all structures with high human occupancy.

Halogen-Free Low Smoke Cables: N2XH and NHXMH

Two terms frequently encountered when discussing fire safety are N2XH and NHXMH. Both fall into the category of “Halogen-Free, Flame Retardant” cables and possess LSZH (Low Smoke Zero Halogen) properties.

What Does Halogen-Free (HF / LSZH) Mean? Halogens (Chlorine, Fluorine, Bromine, Iodine) are elements found in many standard cable insulation and sheath materials (especially PVC). During combustion, these elements transform into highly toxic and corrosive gases. LSZH cables, however, are made from special polymer compounds that do not contain these halogens. As a result, during a fire:

- They produce significantly less and lighter-colored smoke (tested according to IEC 61034 standard).

- They do not release toxic and corrosive gases (tested according to IEC 60754 standard).

- They retard the spread of flame (tested according to IEC 60332-1 and often IEC 60332-3 standards).

N2XH and NHXMH Cables:

Both N2XH and NHXMH are essentially LSZH, flame-retardant cables typically used in fixed installations. While there might be minor differences in their applications and some technical details, their primary purpose is to prevent the release of toxic gases, reduce smoke density, and slow down flame propagation during a fire. They are particularly preferred for use in escape routes, emergency exits, and general building installations. Although these cables will eventually lose their function when directly exposed to fire for a prolonged period, they buy valuable time for evacuation by slowing the fire’s growth and maintaining a less toxic environment.

Circuit Integrity Cables: N2XH FE 180

Another critical aspect of fire safety is ensuring that emergency systems continue to operate during a fire. This is where “circuit integrity” cables come into the picture. N2XH FE 180 is one of the most well-known examples of this type of cable.

What Does FE 180 Mean? “FE” (Function Integrity / Funktionserhalt Elektrik) refers to the cable’s ability to maintain electrical conductivity under fire conditions for a specified duration. “180” represents this duration in minutes (i.e., 180 minutes = 3 hours). These cables, thanks to special insulation layers (often mica tape), can protect their conductors even when exposed to high temperatures and direct flames, continuing to transmit power or signals. These properties are tested according to demanding standards like IEC 60331 or EN 50200.

Applications of N2XH FE 180: These cables are used in systems whose operation is vital during a fire:

- Emergency Lighting Systems

- Fire Alarm and Detection Systems

- Emergency Public Address Systems

- Smoke Control and Extraction Systems (Fans)

- Firefighting Systems (Water pumps, etc.)

- Emergency Elevators

- Power supply for critical equipment like life support units in hospitals

N2XH FE 180 cables possess both LSZH properties (low smoke, halogen-free) and provide circuit integrity. This combination enhances evacuation safety while guaranteeing that essential systems for firefighting and emergency management remain operational.

Relevant Standards and Regulations

Numerous international and national standards define the performance and reliability of fire-resistant cables. Key ones include:

- IEC 60332 Series: Tests the resistance of cables to flame propagation (IEC 60332-1 for single vertical cable test, IEC 60332-3 for bunched vertical cable test).

- IEC 60754 Series: Measures the acidity and corrosivity of gases released during combustion (Halogen content test).

- IEC 61034 Series: Measures the density of smoke produced during combustion.

- IEC 60331 / EN 50200 / BS 6387 CWZ: Tests the ability of cables to maintain circuit integrity (FE) under fire conditions for a specified duration.

In addition to these international standards, national building codes and fire safety regulations dictate the fundamental rules for fire safety in structures, including requirements for materials, installations, and systems. It is mandatory for fire safety cables used in projects to comply with these relevant regulations and standards.

Correct Cable Selection and Application in Projects

Ensuring fire safety in a project involves not only selecting the right cable but also ensuring its correct application. Key considerations during selection and application include:

- Risk Assessment: A risk analysis should be conducted considering factors like the building’s purpose, size, number of floors, and occupant load.

- Correct Type Selection: While LSZH cables (like N2XH, NHXMH) may suffice for escape routes, circuit integrity cables (like N2XH FE 180) must be chosen for critical emergency systems.

- Standards Compliance: Verification through documentation that the selected cables meet the required national and international standards for the project is essential.

- Proper Installation: Cables must be installed without damage, using appropriate connection equipment (terminals, junction boxes, etc.), and laid according to standards. For circuits requiring integrity, other installation components (cable trays, support systems, etc.) must also be appropriately fire-rated.

- Reliable Supplier: Working with reliable suppliers who offer quality-certified, standards-compliant products and can provide technical support is crucial for project safety.

Conclusion: Don’t Compromise on Safety

Fire-resistant cables (like N2XH, NHXMH, N2XH FE 180) are an indispensable safety component of modern structures. They perform critical tasks such as slowing flame spread, preventing the formation of toxic gases and dense smoke, and, most importantly, ensuring the operation of emergency systems to protect lives and property during a fire. Selecting the appropriate cable type for the project, adhering to relevant standards and regulations, and ensuring correct installation are vital for minimizing the impact of a potential fire disaster. Remember, safety lies in the details, and choosing the right cable is one of the most significant details. Never compromise on quality and standards when it comes to safety.