Introduction: The Biggest Misconception in Switching to Halogen-Free Cables

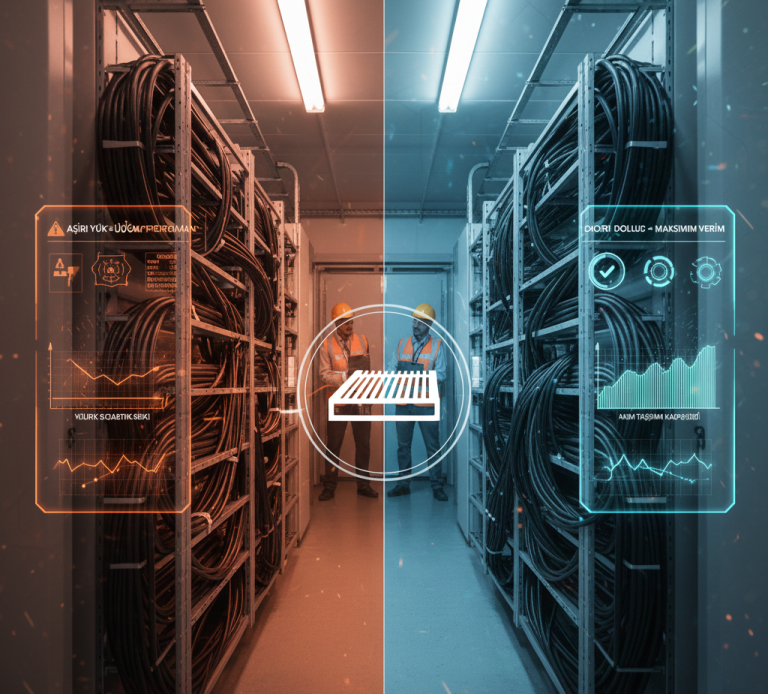

In modern buildings—especially in high-occupancy areas or where evacuation is difficult, such as hospitals, schools, shopping centres, tunnels, and data centres—the use of Halogen-Free Cables (LSZH – Low Smoke Zero Halogen) is mandatory for fire safety. The core purpose of these cables is to prevent flame propagation, minimize the emission of toxic and corrosive gases, and most crucially, ensure low smoke density to facilitate safe evacuation.

However, critical differences exist among cables sold under the “halogen-free” label. Simply specifying “N2XH Cable shall be used” in technical specifications is, unfortunately, one of the biggest critical errors made. The real danger in a fire often comes not from the flame itself, but from the dense smoke and toxic gases produced.

In this article, Delta Tema Elektrik goes beyond the technical definition of N2XH cables to examine the fine details within fire safety standards (specifically smoke density and acid emission). We will explain why choosing the correct Halogen-Free (HFFR – Halogen Free Flame Retardant) cable is vital for your project’s safety and compliance, particularly concerning Halogen-Free Cable Selection.

1. What is N2XH Cable and What Does It Mean?

N2XH is a cable type using standard German (VDE) coding and generally signifies the following characteristics:

- N (Normenleitung): Denotes a standard cable type.

- 2X (Insulation Material): Indicates Cross-Linked Polyethylene (XLPE) insulation. This enhances the cable’s resistance to high temperatures, allowing it to withstand up to 90°C continuously.

- H (Sheath Material): Halogen-Free Outer Sheath (HFFR). This sheath does not release toxic halogen gases (Chlorine, Fluorine, etc.) during a fire.

N2XH cables inherently possess flame-retardant properties and are halogen-free. However, three main standard tests determine if a cable is genuinely safe and compliant with fire safety standards: Flame Retardancy, Halogen Acid Emission, and Smoke Density.

2. The Smoke Density Standard: The Life-Saving Critical Difference (IEC 61034)

Most technical specifications focus on the IEC 60332 standard, which prevents flame spread. Yet, the standard that is truly critical in terms of evacuation and human life safety is the Smoke Density standard.

Smoke instantly reduces visibility to zero, causing panic and preventing people from finding escape routes. Dense smoke, combined with toxic gases, is the primary cause of fatalities in fires.

| Standard Name | Purpose | Accepted Limit |

| IEC 60332 (Flame Retardancy) | Tests the cable’s resistance to vertical flame spread. | The flame must not reach the cable’s upper end by the end of the test. |

| IEC 60754 (Halogen Emission) | Tests the acidity level of gases released during combustion. | The acid content (pH value) of the gas must be greater than 4.3. |

| IEC 61034 (Smoke Density) | Tests the light transmittance of the smoke generated during combustion. | Light transmittance must be 60% or higher. |

The Critical Point (IEC 61034): The fact that a cable is N2XH does not automatically mean it passes IEC 61034 (High Light Transmittance). Some lower-quality halogen-free cables may not spread flame or emit acid but can produce excessively dense smoke, making evacuation impossible. Therefore, technical specifications must explicitly demand compliance with IEC 61034-2 in addition to the N2XH designation.

Link: For a deeper understanding of the international standards governing cable flammability and smoke density test methodologies, essential for high-integrity projects, consult this external resource:https://www.iec.ch/

3. Halogen Acid Emission: Equipment Protection (IEC 60754)

The second major danger after smoke density is the acidic gases created by burning plastic materials during a fire.

When halogen-containing materials like PVC burn, corrosive and toxic gases like Hydrogen Chloride (HCl) are released. These gases not only directly harm human health but also cause severe corrosion damage to the facility’s steel structures, electronic boards, servers, and other sensitive equipment, leading to irreversible losses.

The Halogen-Free (HFFR) sheath material is tested according to the IEC 60754 standard, which measures the pH value of the gases released during combustion. A high pH value (low acidity) indicates that the gases are non-corrosive. This standard is vital not only for life safety but also for the protection of expensive electronic equipment and maintaining Circuit Integrity (E30/E90) for critical systems.

4. Impact of the Correct Halogen-Free Cable Selection on Project Cost

The initial investment cost of a quality, certified halogen-free cable (N2XH/LSZH/HFFR) is higher than that of a standard PVC cable. However, this cost must be evaluated within the Total Project Cost (TPC):

- Direct Cost: The cost of loss of life or failure to evacuate during a fire (incalculable).

- Indirect Cost: The cost of extended evacuation due to smoke, and the repair/replacement cost of servers and electronic equipment damaged by acidic gases.

Choosing a cable that has only the “halogen-free” label but high smoke density represents false optimization in the project and carries the risk of a potential disaster.

As Delta Tema Elektrik, we strongly recommend using HFFR cables from reliable manufacturers (e.g., Prysmian AFUMEX series), which are proven to pass all tests—including IEC 61034 (smoke density) and IEC 60754 (acid emission)—in addition to the N2XH code. This full compliance ensures adherence to the European CPR regulation classification where applicable.

Link: To examine the technical documentation on CPR and Halogen-Free products from a manufacturer providing global solutions in fire safety and cables, use this resource:https://www.prysmian.com/

Conclusion: Do Not Forget the 3 Criteria in Your Specifications

Instead of solely focusing on the N2XH code in your halogen-free cable specifications, you must demand and verify with certificates the following three criteria that measure the cable’s true fire performance:

- Flame Retardancy: IEC 60332

- Halogen Acid Emission (Corrosion): IEC 60754

- Low Smoke Density (Evacuation): IEC 61034-2

The correct cable choice is the most fundamental and crucial engineering decision that secures the safety of your building and the people within it. Contact us immediately for the most suitable and internationally compliant cable solutions. Contact Delta Tema Elektrik for Reliable Halogen-Free Cable Solutions