Introduction: Why Power Quality Is Not Just a Cost Item

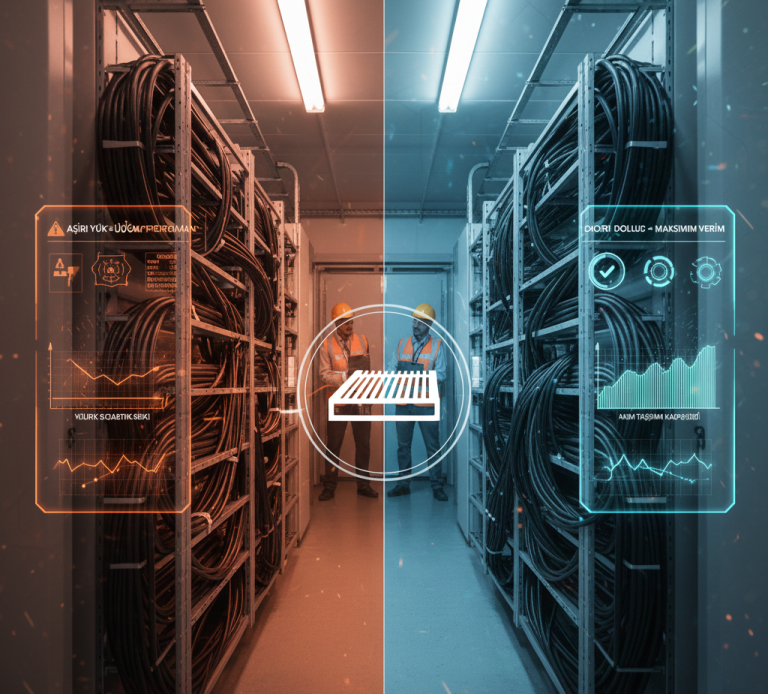

In today’s industrial and commercial facilities, the continuous presence of electrical energy is no longer sufficient; what is truly critical is the Power Quality of that energy. Power Quality refers to the absence of distortions in voltage, current, and frequency, or their adherence to specific limits. Poor quality power leads to equipment failures, unexpected downtime, shortened system life, and most importantly, high energy bills.

As your project partner, Delta Tema Elektrik does not just supply materials; we offer solutions engineered for the long-lasting and efficient operation of your energy infrastructure. The two most common problems degrading Power Quality—Low Power Factor and Harmonics—form the main topic of this post. Effective solutions to these issues, namely Power Factor Correction (PFC) and Harmonic Filtering, are cornerstones of modern facility management and electrical system optimization.

1. Low Power Factor: The Hidden Cost of Reactive Power

A. What is Power Factor (PF)?

Power factor is the ratio between the Active Power (kW) actually used by the equipment and the Apparent Power (kVA) drawn from the grid.

$$\text{Power Factor (PF)} = \frac{\text{Active Power (kW)}}{\text{Apparent Power (kVA)}}$$

Inductive loads (motors, transformers, ballasts) draw Reactive Power (kVAr) from the grid to create a magnetic field. This reactive power performs no useful work but increases the current on the grid, thus overloading transformers and cables and contributing to temperature rise in cables.

B. Negative Impacts of Low Power Factor on the Facility

- High Energy Cost: If consumption exceeds the limits set by the Energy Market Regulatory Authority (EPDK) (leading to a power factor penalty), businesses are obligated to pay Reactive power penalties.

- Capacity Loss: Reactive power fills the current carrying capacity of transformers, switchgear, and cables. This reduces the facility’s capacity to draw active power (kW).

- Voltage Drop: High current causes greater voltage drop across the cables, leading to inefficient and erroneous equipment operation.

C. Solution: Power Factor Correction (PFC) Systems

PFC systems compensate for reactive power locally, typically using automatic or fixed Capacitor banks. This is essential for proper reactive power compensation.

- Automatic Compensation Panels: Consist of stepped capacitor groups that engage and disengage based on load changes. This system is highly preferred for managing inductive reactive power.

- Reactive Power Control Relays: Continuously monitor the system and engage or disengage capacitor steps to bring the power factor to the set target (usually between 0.95 and 1.00).

The internationally compliant products we offer at Delta Tema Elektrik help you maximize the reliability and precision of these systems, leading to substantial industrial energy savings.

Link: For relevant technical details on the correct selection of contactors and relays used in power factor correction systems, you can access the information here:https://deltatema.com.tr/urun-kategorisi/gu-faktor-kontrol/

2. Harmonics: Damages from Contaminated Current and Power Quality

A. What is Harmonic Distortion?

Harmonics are sinusoidal current or voltage components that are integer multiples of the fundamental frequency (50 Hz in Turkey). These distortions are generated by non-linear loads (such as VFDs, UPS systems, and LED drivers) commonly used in today’s facilities. The resulting high levels of Harmonic current lead to serious system issues.

B. The Dangerous Effects of Harmonics

Harmonics distort the pure sinusoidal waveform of the grid voltage, leading to severe problems:

- Capacitor Failures: Harmonics cause resonance, leading to overcurrent and overvoltage in compensation capacitors, which can cause them to fail or quickly shorten their lifespan. This is a critical factor when discussing Harmonics and transformers.

- Transformer Overheating: Harmonic currents cause excessive heat rise (Skin Effect) in transformer windings, degrading insulation and shortening transformer life.

- Protection Relay Errors: Harmonics can cause protection and metering relays to give erroneous readings and lead to nuisance tripping.

- Neutral Line Overload: Specifically, the 3rd harmonics accumulate on the neutral line in three-phase systems, potentially exceeding the line’s capacity and causing a fire hazard (known as Neutral line overload).

C. Solution: Harmonic Filtering Applications

Two primary filtering methods are used for Harmonic mitigation:

1. Passive Harmonic Filters

These are LC circuits consisting of coils and capacitors designed to block or shunt a specific harmonic frequency.

- Advantage: Low cost and reliable.

- Disadvantage: They only filter the specific harmonic level they were designed for; they cannot adapt to load changes and carry a resonance risk.

- Area of Use: Facilities with fixed loads or where a specific harmonic level is dominant.

2. Active Harmonic Filters (AHF)

These filters measure the harmonic current in the system and generate a current of the same magnitude but in opposite phase, neutralizing the harmonics instantaneously. They are the ideal solution for systems with high Total Harmonic Distortion (THD).

- Advantage: They react instantly to load changes, filter a wide range of harmonics (between 3rd and 50th), and do not create a resonance risk. They can also perform Power Factor Correction duties.

- Area of Use: Modern manufacturing facilities and critical centers (data centers) with high-speed load changes.

Link: To review the product portfolio of OBO Bettermann, Delta Tema Elektrik’s solution partner, which sets global standards for harmonic filtering and grounding solutions in modern installations, please visit this link:https://www.obo.de/en/products/search?q=harmonik+filtre

3. Impact on Total Project Cost (TPC) and the Engineering Approach

Although investment in PFC and harmonic filtering systems may seem like an added cost at first glance, it is a strategic decision that reduces the Total Project Cost (TPC) in the long run.

| Area of Improvement | Cost Reduction Effect |

| Reactive Penalties | Provides a direct reduction in the energy bill. |

| Equipment Lifespan | Reduces failures and replacement costs for transformers, motors, and capacitors. |

| System Capacity | Ensures the existing infrastructure (transformer, cable) carries full capacity active power (kW), eliminating the need for early infrastructure upgrades. |

| Fault Downtime | Guarantees production continuity by preventing nuisance tripping and unexpected shutdowns. |

Remember: Compensation and filtering solutions must be integrated from the very start of the project with a proper Power Quality Analysis that reflects the facility’s load profile. Delta Tema Elektrik is ready to support you in this optimization process with our supply of internationally compliant materials and our accumulated engineering expertise.

Conclusion: Power Quality is the Key to Efficiency

Improving Power Quality is not just about meeting legal requirements; it is an investment decision that directly impacts operational efficiency and profitability. By eliminating problems like low power factor and harmonics with the correct PFC and Active/Passive Filtering solutions, you can make your facility more reliable, longer-lasting, and most importantly, less costly.

Contact us for the right product and engineering support to raise the Power Quality in your projects to international standards. Delta Tema Elektrik Contact Page for Rational Energy Solutions