The Using Modular Profiles approach has revolutionized the construction and installation industry, especially concerning support systems for electrical, mechanical, and piping infrastructures. Far from being a mere component, these profiles represent a paradigm shift that directly impacts the Return on Investment (ROI) of any project. In this detailed analysis, we will examine how the adoption of these systems not only optimizes installation time but also offers significant long-term savings, consolidating a more agile and economically viable working method.

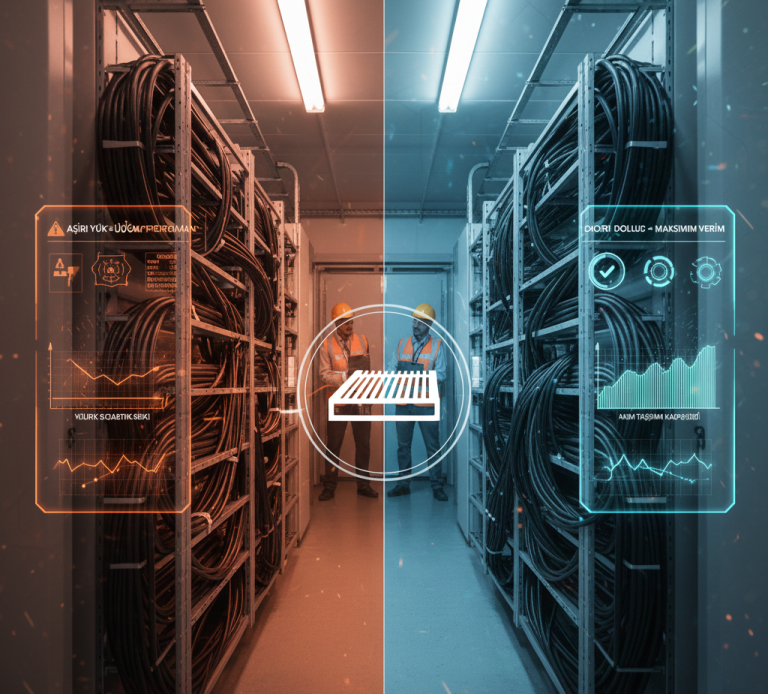

The Starting Point: The Inefficiency of Classical Methods

Historically, installers have relied on mounting solutions involving welding or in situ drilling. These processes are inherently slow, require highly specialized personnel, and generate a high level of waste and debris on the job site. The fundamental philosophy behind Using Modular Profiles is to eliminate these inefficiencies at the root. These prefabricated systems, which are assembled through purely mechanical joints (weld-free assembly and without the need for dangerous thermal treatments), allow for unparalleled flexibility and speed on the job site. This standardization, in turn, simplifies planning and inventory management.

Speed as an Accelerator of ROI (Return on Investment)

Time is, unquestionably, the most valuable resource and often the most costly factor in a large-scale construction project. Every day saved on the project schedule translates directly into a substantial reduction in labor costs and faster commissioning of the infrastructure, meaning invested capital is freed up much sooner.

- Reduction of Installation Time: Modular systems have the proven ability to reduce assembly time by up to 40% compared to traditional methods, and even more in projects with repetitive designs. An experienced installer can simply cut the profile to the required size (if pre-cut components are not used) and join it to other elements using specialized bolts and nuts. This process requires minimal tools, reduces the risk of costly errors, and minimizes operational downtime. This advantage is maximized in complex and vertical installations, such as those requiring floor-to-ceiling assemblies at great heights.

- Less Reliance on Specialized Labor: Tasks such as welding, metal cutting, and heavy equipment handling require specific certifications and highly refined skills. Using Modular Profiles, being essentially a “precision assembly” process with a clear manual, can be performed by personnel with basic or intermediate training, thus drastically reducing hourly labor costs and diminishing critical reliance on a limited group of professionals.

Key Components and Their Direct Impact on Efficiency

A modular profile should not be viewed only as a simple metal channel with holes. It is, in fact, an entire ecosystem of components meticulously designed to work together, precisely optimizing every step of the installation process.

The Strategic Role of Connectors and Accessories

Modular connectors, brackets, joining plates, and anchor supports are designed with predefined slots, holes, and patterns that fit perfectly and without play with the profiles. This millimeter precision eliminates the need for constant measurements, markings, and complex in situ adjustments. The ability to adjust the position of a support, rotate a bracket, or change the route of a conduit in a matter of minutes—instead of hours of welding and cutting—is an invaluable benefit that directly contributes to the ROI Analysis of the project. To learn more about compatible accessories and their certifications, consult our Modular Profile Accessories Guide.

Logistics Optimization and Sustainability

The design of the profiles is not only technical but also logistical. Their stackable shape, optimized weight, and smart packaging reduce transport and storage costs in the supply chain. A lower volume of material on the job site not only means fewer logistical problems and space requirements but also a reduced carbon footprint in the supply chain—a benefit that resonates with modern standards of sustainability and corporate social responsibility.

Quantitative Analysis of Savings and ROI Justification

To fully understand the ROI, it is essential to set aside qualitative estimations and focus on the numbers. Let’s consider a large-scale electrical or mechanical infrastructure project with a requirement of 10,000 meters of support:

The basic Return on Investment (ROI) formula is:

$$\text{ROI} = \frac{(\text{Cost Saved – Additional Material Cost})}{\text{Additional Material Cost}} \times 100$$

| Cost Factor | Traditional Method (Welding/Drilling) | Using Modular Profiles | Estimated Savings |

| Labor Cost | 1000 hours of specialized work (High cost/hour) | 600 hours of general work (Medium cost/hour) | $40\%$ in installation time and $>40\%$ in total labor cost |

| Material Waste | High (due to cutting errors, failed welds, and modifications) | Minimal (precise cuts, reversible assembly, and reuse of parts) | Waste reduction of $15\%$ to $20\%$ |

| Tools and Consumables | Welding equipment, gases, cutting discs, power sources | Basic hand tools, torque wrenches, manual cutters | Lower spending on consumables and energy |

| Inspection and Certification | High (Non-destructive testing of welds) | Low (Visual inspection and torque verification on mechanical joints) | Inspection and documentation time reduced by half |

The $40\%$ savings in installation time mentioned is an average and conservative figure that can be greatly exceeded in environments with difficult access, restricted hot work conditions, or adverse weather conditions.

The Advantage in Durability and Maintenance

The ROI of modular systems extends far beyond the installation phase.

The profiles are typically made of high-quality hot-dip galvanized steel or special corrosion-resistant materials, ensuring a significantly longer lifespan. This robustness is vital for the system’s longevity.

[INTERNAL LINK – SEO Correction]: If you want to know more about how corrosion or poor Power Quality can affect the lifespan of your electrical equipment and infrastructure flexibility, read our analysis: https://deltatema.com.tr/blog/calidad-de-energia-correccion-pfc-filtros/ (This link is an example of an internal link to the previous power quality blog post)

The infrastructure flexibility offered by modular systems allows adding a new support point or modifying the route of a cable/conduit with minimal interruptions. There is no need to dismantle or cut the entire structure; simply loosen, readjust, and re-tighten the components. This flexibility drastically reduces future remodeling or expansion costs.

Conclusion: More Than Just a Profile

The Using Modular Profiles approach is a strategic investment decision that results in a superior Return on Investment. It is not simply the purchase of a product, but the investment in a comprehensive working method that is faster, safer, inherently more precise, and much more adaptable to the dynamic needs of modern infrastructure. The quantifiable benefits in reducing labor costs, minimizing material waste, and the increased longevity of the installation, along with the ease of future modifications, fully justify the transition to these systems.

Companies that adopt this technology are not only building solid infrastructures but are also building sustainable efficiency and a guaranteed ROI.

To begin your journey toward optimized installation and discover how Using Modular Profiles can transform your next project, we invite you to contact us. Contact Delta Tema Elektrik for Modular Solutions